Introduction to Modified Atmosphere Packaging

Modified Atmosphere Packaging (MAP) has become a pivotal innovation in the packaging industry, significantly impacting the way products are preserved and presented in today’s market. The essence of MAP lies in altering the atmosphere inside the packaging to enhance the shelf life and quality of the products, particularly in the food sector. This technique has gained widespread adoption across various industries due to its ability to extend freshness, reduce spoilage, and maintain the original taste and appearance of products over longer periods.

Recognizing the burgeoning importance of MAP, Chuanglibao Packaging Machinery Co., Ltd. ventured into the research and development of MAP machines starting in 2014. Over the years, their dedicated efforts have culminated in sophisticated technology that meets the high standards required for effective packaging solutions. Their advancements are particularly beneficial for small and medium-sized enterprises (SMEs), which often seek cost-effective yet high-quality packaging options.

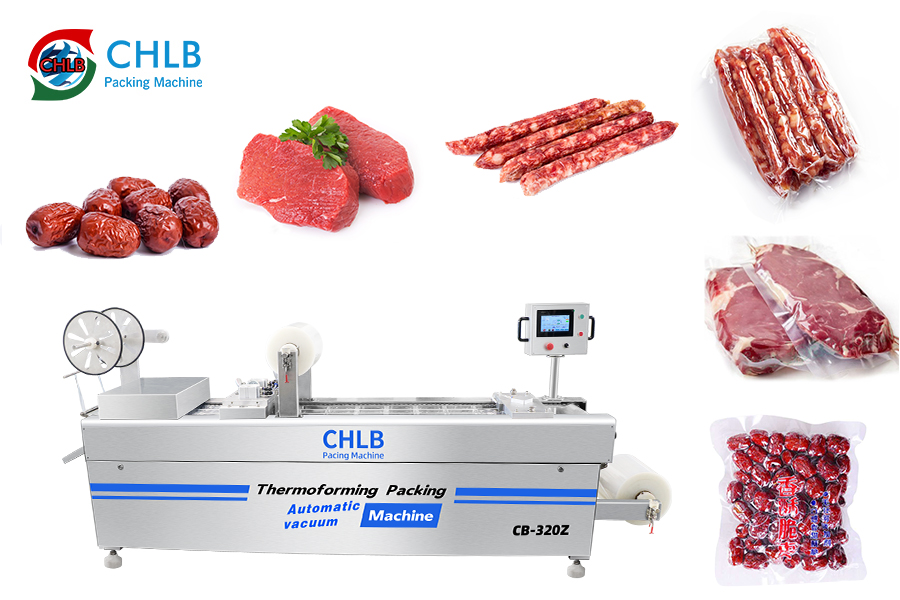

One of the flagship models emerging from their research is the CB-320Z. This model is tailored to meet the diverse needs of SMEs by offering a perfect blend of affordability and advanced packaging technology. The CB-320Z not only embodies the technical prowess of CHUANGLIBAO but also signifies a commitment to making MAP accessible to businesses of various scales. With such innovations, firms can better compete in the marketplace by leveraging the enhanced capabilities of Modified Atmosphere Packaging.

The Science Behind Modified Atmosphere Packaging

Understanding the Technology

Modified Atmosphere Packaging (MAP) is an innovative technique designed to extend the shelf life of perishable food products by altering the atmosphere surrounding them. At its core, MAP involves replacing the air inside a package with a specific mixture of gases tailored to the particular needs of the product being preserved. Common gases used in MAP include nitrogen, carbon dioxide, and oxygen, each serving a specific function to inhibit microbial growth and slow down the deterioration process.

The technology begins by extracting the natural air from the package, which primarily consists of nitrogen (78%), oxygen (21%), and trace amounts of other gases. This ambient air is then replaced with a carefully calibrated gas mixture. For instance, high concentrations of carbon dioxide are often employed to suppress the growth of bacteria and mold, while oxygen levels are minimized to reduce oxidative spoilage. Simultaneously, nitrogen, an inert gas, is used to fill the space and maintain package integrity without reacting with the food.

MAP systems are adaptable and can vary depending on the type of product and its specific storage requirements. Fresh meat, for example, benefits from a high-oxygen environment to retain its red color, while ready-to-eat salads might require low oxygen levels to prevent wilting. Advances in MAP technology also enable dynamic adjustments where the gas composition can change over time to further optimize preservation.

Another cornerstone of MAP technology is the integrity and quality of the packaging materials used. Films with selective permeability play a crucial role in maintaining the desired gas mixture within the package, ensuring that external factors such as light and humidity do not compromise the product. The packaging material must be robust enough to create an effective barrier while being flexible enough to withstand the rigors of transportation and handling.

Incorporating MAP into the food supply chain yields several benefits. It prolongs freshness, reduces food waste, and allows for longer distribution times, enabling producers to reach wider markets. Furthermore, the technology supports the growing consumer demand for minimally processed, fresh, and high-quality food products.

To sum up, Modified Atmosphere Packaging leverages a sophisticated interplay of gases and specialized materials to significantly enhance food preservation. This technology not only meets the needs of modern consumers but also contributes to a more sustainable and efficient food industry.

Key Components and Processes

Modified Atmosphere Packaging (MAP) relies heavily on the precise control and application of various gases to extend the shelf life of fresh produce, meats, and other perishable goods. The efficacy of the entire packaging process hinges on high-quality components and precise execution, which is why industry leaders such as Chuang Li Bao Packaging Machinery Co., Ltd. opt for top-tier electrical and mechanical parts. They employ advanced components from renowned manufacturers like Siemens, Airtac, Rietschle, and Schneider Electric, ensuring robust and reliable performance in their MAP solutions.

For instance, Siemens provides advanced automation systems that enable precise control over gas mixture ratios and packaging conditions. Their programmable logic controllers (PLCs) and human-machine interfaces (HMIs) are essential for maintaining the consistency and accuracy required in MAP processes. Airtac, known for its high-quality pneumatic components, delivers solutions that support efficient gas flow and pressure regulation, which are critical for maintaining the ideal packaging environment.

Rietschle’s vacuum and pressure technologies come into play to create the necessary atmosphere within the packaging, whether it involves removing oxygen or injecting specific gas blends. Their advanced equipment ensures that the desired atmospheric conditions are achieved quickly and consistently, reducing the likelihood of contamination or spoilage.

Lastly, Schneider Electric’s contributions to MAP machinery involve providing reliable electrical components and systems that ensure seamless operations. Their energy-efficient and durable solutions help maintain the optimal functioning of packaging machinery, further enhancing the overall efficiency and reliability of MAP.

By integrating these top-of-the-line components from Siemens, Airtac, Rietschle, and Schneider Electric, Chuang Li Bao Packaging Machinery Co., Ltd. not only enhances the performance and reliability of their packaging systems but also ensures that the stringent requirements of modified atmosphere packaging are consistently met. This integration of advanced technologies underpins the effectiveness of MAP in preserving product freshness and extending shelf life.

Types of Gases Used in MAP

Common Gases and Their Roles

In Modified Atmosphere Packaging (MAP), several types of gases are commonly used to extend the shelf life of fresh food products while maintaining their quality. The choice of gas or gas mixture largely depends on the type of food being packaged. Here we’ll explore some of these gases and their specific roles:

- Carbon Dioxide (CO₂) Carbon dioxide is perhaps the most critical gas in MAP applications. Its primary function is to inhibit the growth of aerobic microorganisms including mold, yeast, and some bacteria. By doing so, CO₂ extends the shelf life of a wide range of perishable foods such as meat, poultry, and dairy products. Typically used in concentrations of 20-60%, carbon dioxide can sometimes dissolve into the moisture of the food, slightly affecting its taste and texture.

- Nitrogen (N₂) Nitrogen is an inert gas, meaning it doesn’t react with the food products. Its main role in MAP is to displace oxygen to prevent oxidative rancidity and other spoilage reactions. Nitrogen is commonly used in snacks, coffee, and dried fruit packaging where its inertness ensures that the flavor and texture of the products remain unchanged. It’s often used in combination with other gases to balance the atmosphere inside the packaging.

- Argon (Ar) Argon is another inert gas used for its high density and low solubility in water. Although not as commonly used as nitrogen, argon can displace oxygen efficiently, making it an excellent choice for sensitive food items like wine and other beverages. Its role in maintaining freshness without altering the food’s sensory attributes makes it valuable in niche applications.

Oxygen Reduction: The Critical Factor

One of the most pivotal components in Modified Atmosphere Packaging (MAP) is the reduction of oxygen within the packaging environment. Oxygen can drastically affect the shelf life and quality of perishable goods. The presence of oxygen promotes the growth of aerobic microorganisms and accelerates oxidative rancidity, leading to spoilage, discoloration, and off-flavors. Therefore, managing oxygen levels is crucial to maintaining product integrity.

To achieve optimal oxygen reduction, a mix of gases such as nitrogen (N₂) and carbon dioxide (CO₂) are commonly employed. Nitrogen acts as an inert filler gas that displaces oxygen, creating an environment unsuitable for aerobic microorganism growth. It is particularly favored for its non-reactive nature, ensuring that it does not interact with the food product and alter its flavor or texture.

Carbon dioxide, on the other hand, plays a dual role. It not only displaces oxygen but also possesses antimicrobial properties, inhibiting the growth of spoilage organisms and some pathogenic bacteria. For instance, in the packaging of meat products, a higher concentration of CO₂ helps maintain the red color of fresh meat, which is attractive to consumers, while slowing down spoilage.

Advanced MAP systems may also utilize argon (Ar), an inert gas that can replace nitrogen in certain applications. Argon is denser than air, providing an additional barrier to oxygen ingress. Though more costly, it can be advantageous for premium products where exceptional quality retention is paramount.

In summary, oxygen reduction through the strategic use of gases like nitrogen, carbon dioxide, and even argon, is a critical factor in extending the shelf life and preserving the quality of perishable goods in MAP. Efficient oxygen management directly correlates with the success of the packaging system, making it a cornerstone practice in food preservation technology.

Conclusion

Modified Atmosphere Packaging (MAP) is a technology that effectively extends the shelf life of products by replacing the air inside the packaging with other inert gases. This advanced packaging technology can slow down the oxidation and spoilage process of food, maintain the freshness of products, and is widely used in various food fields.

In the field of modified atmosphere packaging, Chuanglibao Packaging Machinery Co., Ltd. has accumulated rich experience and advanced technology through 10 years of continuous research and technological improvement. They are able to provide a variety of modified atmosphere packaging solutions for large, medium and small enterprises to meet the needs of different customers. Among them, model CB-320Z has become the first choice of small and medium-sized enterprises due to its compact design, affordable price and superior packaging performance. This equipment not only improves production efficiency, but also significantly extends the shelf life of products, bringing practical economic benefits to the company.

By using Chuanglibao’s modified atmosphere packaging solutions, companies can not only improve product quality and brand competitiveness, but also occupy a more favorable position in the market and meet consumers’ demand for high-quality products. In short, the widespread application of modified atmosphere packaging technology and the professional solutions of Chuanglibao Company are driving the entire food packaging industry to develop in a more efficient, environmentally friendly and safe direction.