Food packaging has evolved significantly, particularly in the ready-to-eat (RTE) food sector. RTE foods, such as salads and microwaveable meals, cater to busy consumers seeking convenience without sacrificing taste or nutrition. To maintain efficiency, hygiene, and food quality, advanced packaging machinery is essential. Ready-to-eat food packaging machines ensure the safety and freshness of these products. في هذا الدليل, we’ll explore different types of RTE food packaging machines, their working processes, benefits, and key considerations for selecting the right one for your business.

What is Ready-to-Eat (RTE) طعام?

Ready-to-eat food refers to food products that are pre-prepared and packaged, allowing consumers to eat them immediately or with minimal preparation. These foods often come in single-serving sizes and are designed for convenience. Examples of RTE food include:

- Pre-packaged sandwiches

- Frozen meals

- Salads

- وجبات خفيفة

- Dips

- Pre-cooked meats

The key advantage of RTE foods is their ease of use. They eliminate the need for cooking or extensive preparation, making them ideal for people with busy lifestyles. لكن, to maintain the quality and safety of these foods, they need to be packaged in a way that preserves freshness and extends shelf life.

What are Ready-to-Eat (RTE) Food Packaging Machines?

RTE food packaging machines are specialized machines designed to package ready-to-eat foods in a variety of formats, such as trays, الحقائب, or vacuum-sealed bags. These machines perform critical tasks like filling, ختم, وضع العلامات, and inspecting the packaged food products. The goal is to create a package that ensures the food remains safe to eat, retains its quality, and is convenient for the consumer.

Packaging is not just about protecting food during transport—it plays a significant role in prolonging the shelf life, preventing contamination, and enhancing the overall consumer experience. RTE food packaging machines are engineered to handle different packaging materials, product types, and production volumes, making them an indispensable part of the food manufacturing process.

Types of Ready-to-Eat Food Packaging Machines

There are several types of packaging machines used in the ready-to-eat food industry. Each type offers distinct advantages depending on the specific needs of the food product and production line. Below are some of the most common types of RTE food packaging machines:

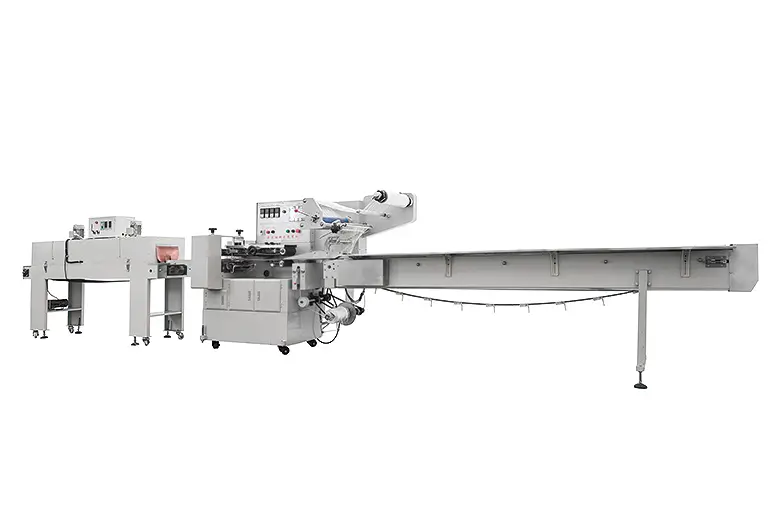

1. Horizontal Form-Fill-Seal (HFFS) آلات

Horizontal Form-Fill-Seal (HFFS) آلات are ideal for packaging solid and semi-solid products like bars, بسكويت, and sandwiches. These machines form a package from a roll of flexible film, fill it with the product, and seal it, all in a horizontal layout. HFFS machines are popular in the food industry due to their speed, براعة, and the ability to handle a wide range of packaging formats.

HFFS machines are particularly useful for products that require flow wrapping, where the product is wrapped in a protective film that provides a tamper-proof seal. These machines are efficient, allowing for high-speed packaging that ensures consistency in portion size and product presentation.

2. Vertical Form-Fill-Seal (VFFS) آلات

Vertical Form-Fill-Seal (VFFS) آلات are designed for packaging powders, حبيبات, السوائل, and other similar products. In a VFFS machine, the packaging material is fed vertically, and the machine forms a pouch, fills it with the product, and seals it. VFFS machines are often used for packaging snacks, قهوة, soups, والصلصات.

This type of machine is widely used in the RTE food industry because it can handle various bag sizes and packaging formats, providing flexibility in the types of products it can package. VFFS machines are known for their high efficiency and ease of operation, making them a staple in many food packaging lines.

3. ماكينات التعبئة والتغليف بالحرارة

ماكينات التعبئة والتغليف بالحرارة are used for packaging products like meats, جبن, والمنتجات الطازجة. These machines use heat to form plastic film into specific shapes or molds, which are then filled with the product and sealed. The packaging is typically vacuum-sealed or modified atmosphere sealed to maintain the freshness of the product.

Thermoforming machines are ideal for packaging products that need extra protection or that require specific mold shapes. They offer enhanced shelf life, as the vacuum or modified atmosphere helps prevent spoilage and extend the freshness of the product. These machines are suitable for packaging a wide range of products, from fresh fruit to deli meats.

4. Heat Shrink Wrapping Machines

Heat Shrink Wrapping Machines are commonly used for packaging products like trays of RTE meals, وجبات خفيفة, and pre-cooked items. In this process, the product is placed inside a shrink film, and heat is applied to shrink the film tightly around the product. The resulting shrink-wrap packaging provides a tamper-evident seal that is durable and visually appealing.

Heat shrink wrapping is ideal for packaging multiple products together or protecting products in irregular shapes. It helps extend shelf life by providing an airtight seal, keeping the food fresh and safe for longer periods. The shrink-wrap also adds a layer of protection during transportation and handling.

How Ready-to-Eat Food Packaging Machines Work

Understanding how RTE food packaging machines work is essential for selecting the right machine for your business. The general process involves several steps:

Overview of the Packaging Process

- Product Filling: The first step in the packaging process is filling the package with the product. This could involve dispensing liquids, حبيبات, or solid foods into pre-formed packages or bags.

- Sealing and Heat Sealing: After the product is filled, the machine seals the package to prevent contamination and preserve freshness. Heat sealing is often used to bond the packaging material, creating an airtight seal.

- Labeling and Inspection: The package is labeled with important product information, such as ingredients, expiration dates, and nutritional details. Quality checks are also performed to ensure that the packaging is intact and that the food meets safety standards.

Automation in Packaging: From Manual to Fully Automated

Automation has revolutionized the packaging process. Modern RTE food packaging machines are highly automated, requiring minimal manual intervention. Automation improves efficiency, reduces human error, and speeds up production, allowing businesses to scale their operations.

على سبيل المثال, fully automated systems can handle product filling, ختم, وضع العلامات, and inspection without the need for operators to intervene. This level of automation not only increases throughput but also ensures that each package is consistently sealed and correctly labeled, minimizing waste and maximizing efficiency.

Advantages of Using RTE Food Packaging Machines

Using RTE food packaging machines offers several key benefits that can improve both production and product quality.

Increased Shelf Life

One of the primary advantages of using RTE food packaging machines is their ability to extend the shelf life of packaged foods. Machines like thermoformers and VFFS machines can apply vacuum sealing or modified atmosphere packaging (خريطة) techniques to remove air and reduce the growth of bacteria. This helps keep the food fresh for a longer period, reducing waste and increasing the product’s value.

Consistent Quality and Portion Control

RTE food packaging machines ensure that each product is packaged consistently. This helps maintain portion control, ensuring that each package contains the right amount of product, which is especially important in the foodservice industry. Consistent quality ensures that customers receive the same experience with every purchase, which is crucial for brand reputation.

Reducing Labor Costs and Waste

من خلال أتمتة عملية التعبئة والتغليف, businesses can reduce labor costs and minimize human error. Machines operate at high speeds with high accuracy, which leads to less product waste. بالإضافة إلى ذلك, automation allows for a more efficient use of materials, reducing the likelihood of damaged or wasted packaging.

Key Features to Look for in an RTE Food Packaging Machine

When choosing an RTE food packaging machine, several features should be considered to ensure that it meets the needs of your business.

Automation and Efficiency

Look for machines that are automated and offer fast processing speeds. This will help increase production efficiency and minimize downtime. Automation also ensures more precise filling, ختم, ووضع العلامات.

Hygiene and Food Safety Compliance

Food safety is a top priority in the packaging industry, especially for RTE foods. Choose machines that meet hygiene standards and are easy to clean to prevent contamination.

Customization Options for Different Products

If your business deals with a wide range of RTE food products, it’s important to select machines that offer customization options for different package sizes, الأشكال, والمواد. Flexibility in packaging design can help cater to various consumer preferences.

Energy Efficiency and Cost-Saving Features

Energy-efficient machines can significantly reduce operational costs over time. Look for packaging machines with energy-saving features to keep costs low while maintaining high performance.

How to Choose the Right RTE Food Packaging Machine for Your Business

Choosing the right machine involves understanding your specific needs and assessing several factors.

Assessing Your Production Volume

Determine how much product you need to package on a daily or weekly basis. Machines with higher throughput capacities are suitable for large-scale operations, while smaller machines may be better for low to medium production volumes.

Understanding Product Characteristics

Different food products have varying packaging requirements. على سبيل المثال, liquids may need a different type of sealing than solid foods, and products that require refrigeration or freezing will require machines that can accommodate temperature-sensitive packaging. Understanding your product’s characteristics is key to selecting a machine that ensures both safety and freshness.

Considering Flexibility and Speed

Your business might face fluctuations in demand, requiring a packaging machine that can adjust to different production volumes and packaging formats. Speed is also an important factor—high-speed packaging machines can help you meet high demand without compromising quality. Make sure the machine you choose offers the flexibility to scale up or down as needed.

Choosing the Right Manufacturer

When selecting a packaging machine, consider the reputation of the manufacturer. يختار a reliable packaging machine manufacturer that offers reliable support and maintenance services, as this will be critical for minimizing downtime and ensuring your machine operates optimally for years to come. It’s also wise to evaluate customer reviews and seek recommendations from other food businesses to ensure you’re purchasing from a trusted source.

خاتمة

Ready-to-eat food packaging machines are crucial for keeping food safe, fresh, and convenient. Options like form-fill-seal, thermoforming, and shrink-wrapping machines cater to various RTE food types. When selecting the right machine, consider production volume, product characteristics, and flexibility. Prioritize hygiene, automation, and energy efficiency to ensure a smooth, cost-effective packaging process. The right choice can streamline operations, تمديد العمر الافتراضي, and deliver consistent, high-quality products to your customers.

الأسئلة الشائعة

What is the average cost of a ready to eat food packaging machine?

The cost of a ready-to-eat food packaging machine can vary widely depending on the type, features, and capacity. On average, prices range from $5,000 ل $100,000. Basic machines like VFFS units might cost less, while more advanced models such as thermoformers or high-speed HFFS machines can be more expensive. It’s important to consider not just the upfront cost, but also the long-term operational and maintenance costs.

Can I customize the packaging machine to suit my product?

نعم, many manufacturers offer customization options for packaging machines to suit specific product needs. This may include custom-sized packaging, the ability to handle unique product shapes, or specific sealing methods. Customization allows you to tailor the machine to your production requirements and ensure optimal results for different types of RTE foods.

What are the maintenance requirements for RTE food packaging machines?

Maintenance requirements vary depending on the machine type, but in general, regular cleaning, lubrication, and inspection are essential to ensure optimal performance. For instance, machines should be cleaned regularly to prevent contamination, especially in food processing environments. بالإضافة إلى ذلك, parts like seals and motors may require periodic replacement to avoid malfunctions and reduce downtime.

How long does it take to receive an RTE food packaging machine from China?

The delivery time for a packaging machine from China typically ranges from 30 ل 90 أيام, depending on factors like the type of machine, production time, and shipping method. Custom machines may take longer due to the need for adjustments or specific configurations. It’s a good idea to plan ahead and allow extra time for shipping and installation.