CHLB Packing Machine supply many kinds of food packaging solution.In one of our case, we received an inquiry from a Russian customer who was looking for the flow packing machine for moon cake.

Customer visited us soon after our initial communication. And replied us a very positive comment. Especially he’s very interested in our servo packing machine since the smart functions.

But this customer requested a highly automatic production, so he preferred a packing line. In the past, the packing line is equipped with a dual frequency packing machine that’s without smart functions. It may occur empty bags or the whole equipment will totally malfunctioned when machine cut the product.

This order from Russia is the first case of servo packing machine equipped with feeding line in China.

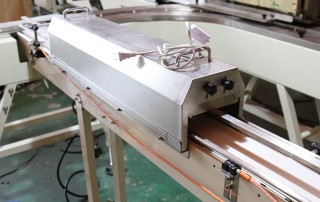

The servo system is more compatible to connect with external equipment, this machine will equipped with Thermal Transfer Printer and Ultra Violet Lamp.

Packing Japanese soft moon cake

Intermittent flow wrap machine for packing Japanese soft moon cake of size: (Diameter70mm * Height 35mm) with: 260mm film

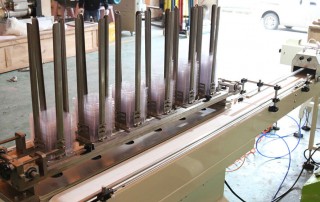

Automatic Feeding unit.

Gas Flushing Kit (N2).

Options

Continuous Thermal Transfer Printer (Ribbon 35mm).

Ultra Violet Sterilizing Tunnel.

Carbon Brush Online with Packing Film, for Electro Static Hazard.

Ultra Violet Lamp for Sterilizing Packing film.

| Output | Up to 100 products per minute Up to 40 m/min film speed Product and film characteristic may affect machine output |

| Size Range | |

| Package cut-off length | 50-6000mm |

| Product width | Max.240mm |

| Product height | Max.80mm |

| Packaging Material Reel | |

| Reel diameter | ≤300mm |

| Core diameter | ≤75mm |

| Packaging material width | Max.500mm |

| Connections | |

| Voltage | 220V,50HZ |

| Power usage | 4.3KW |

| Machine weight | 2000kg |

| Machine dimensions | L9627mm*W1977mm*H1600mm |

| Blade cut type | Rotary cutter |

| Motor configuration | Full servo |

| Optional Device | date printer, auto feeder, gas charger, etc. |

Since it’s not the Japanese moon cake production period, we use other substitute to test and the whole packing line runs very smoothly.

The servo machine is suitable for various products within size range and very easy to switch settings when change product. Customer very satisfied with the testing video and spoke highly of our R&D ability.

Customer’s sure will strengthen our confidence in providing customized packing solution to all of them.