In the food industry, effective biscuit packaging plays a crucial role in preserving freshness, and enhances market appeal. With various packaging types, choosing the right type can make a significant difference in product quality and consumer satisfaction.

This comprehensive guide explores the different biscuit packaging materials, common packaging types, and the machines used in the food industry that facilitate the process.

Keep reading to discover the best solutions for your products, and learn how CHLBPACK, a leading packaging machine supplier, can help take your packaging to the next level.

What is Biscuit Packaging?

Biscuit packaging refers to the process and materials used to encase biscuits, to keep their freshness and quality while protecting them from elements like moisture, light, and physical damage. It typically involves materials like plastic films or cardboard, designed to seal in the product’s flavor and texture.

For manufacturers, biscuit packaging isn’t just about protection—it also serves as a marketing tool. Well-designed packaging can attract consumers, communicate a brand’s message, and stand out on store shelves.

Biscuit Packaging Materials Types

It’s important for us to understand the different packaging materials because it is related to the freshness degree of the biscuits and environmental consciousness. Let’s dive deeper into the biscuit packaging material!

Plastic Films

Plastic films are a practical choice for biscuit packaging, keeping biscuits fresh by locking out moisture. Made from materials like polypropylene, these films are lightweight, tear-resistant, and perfect for sealing in flavor. Plus, they allow brands to showcase their product through transparent or printed designs.

Paper-Based Materials

Paper-based packaging, like cartons and wraps, offers a more eco-friendly option. Treated to keep moisture out, it helps protect biscuits while being sturdy enough to avoid breakage. This type of packaging is recyclable and can be customized with eye-catching designs.

Metal Tin Packaging

Metal tins give biscuits an upscale feel. They protect against physical damage and extend freshness by keeping air and light out. Tins are often reused by consumers for storage, making them a durable and appealing packaging choice, especially for gifts.

Biodegradable Materials

Biodegradable packaging is growing in popularity as it’s made from renewable resources like cornstarch or plant fibers. It offers the same protection as plastic but breaks down naturally, aligning with the shift toward more sustainable and environmentally friendly products.

Common Biscuit Packaging Types

When it comes to packaging biscuits, selecting the right method is crucial for both product quality and consumer appeal. Let’s explore some common biscuit packaging types to find the right type of packaging’s benefits from preserving freshness to enhance the brand’s reputation!

Flow Wrap Packaging

Flow wrap packaging is a popular method for biscuits, where a continuous roll of film wraps around the product. This horizontal flow wrap method efficiently seals each biscuit, providing excellent protection against moisture and extending shelf life. It’s versatile, allowing for various shapes and sizes, making it ideal for mass production.

Pillow Pack Packaging

Pillow pack packaging features a pillow-shaped design, often used for individual or small portions of biscuits. This style provides an appealing presentation while keeping the biscuits fresh. The simplicity of the design makes it cost-effective and easy to produce, perfect for on-the-go snacks.

Tray and Sleeve Packaging

Tray and sleeve packaging is typically used for premium biscuits, offering an elegant presentation. The biscuits are arranged in a tray, which is then covered with a decorative sleeve. This method not only protects the biscuits but also enhances brand visibility and shelf appeal, making it an excellent choice for specialty products.

Stand-Up Pouches

Stand-up pouches are a modern packaging solution that combines convenience with functionality. These resealable pouches provide easy access to biscuits while preserving freshness. They are lightweight and take up minimal shelf space, making them popular for both retailers and consumers looking for practical, portable snacks.

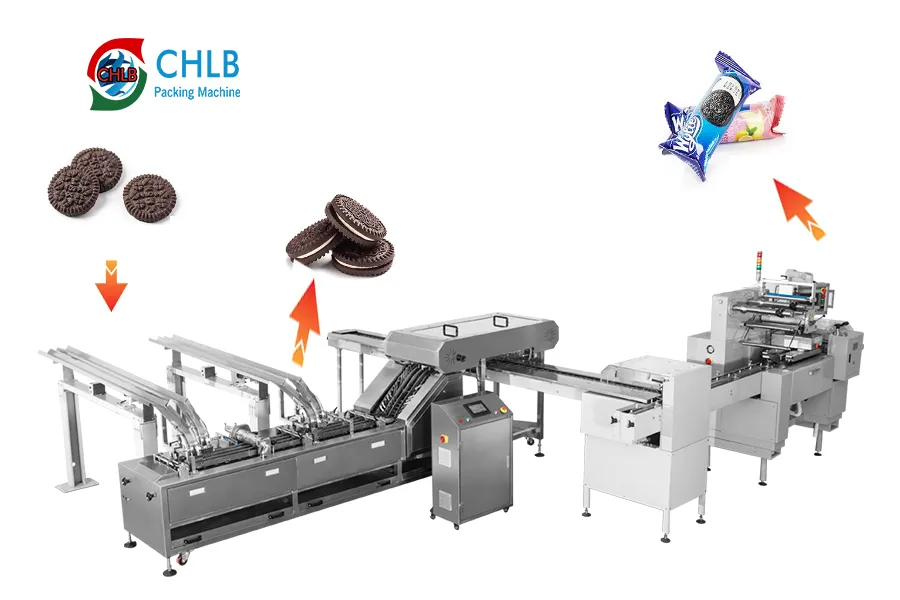

Biscuit Packing Machines for Food Industry

Biscuit packing machines are essential for creating efficient and appealing packaging that keeps biscuits fresh and protected. These machines are key players in the production process, affecting both quality and efficiency.

Horizontal Flow Wrap Machines

Horizontal flow wrap machines play a crucial role in the biscuit packaging industry by efficiently wrapping products in plastic films. This technology utilizes a continuous roll of film that flows horizontally, fully enclosing the biscuits and sealing them to preserve freshness.

The advantages of this approach include its adaptability to various biscuit shapes and sizes, making it a versatile choice for mass production. It’s particularly effective for creating both individual and multipack options, delivering speed and flexibility. Typical applications for horizontal flow wrap machines include packaging biscuits for retail and bulk distribution, where maintaining product freshness and appealing presentation is essential.

Vertical Form Fill Seal (VFFS) Machines

Vertical Form Fill Seal (VFFS) machines offer another effective option for biscuit packaging. These machines operate by forming a pouch or bag from a roll of film, filling it with biscuits, and sealing it in one seamless process. The benefits of VFFS machines include high efficiency, a compact footprint, and the capability to produce pillow packs or stand-up pouches suitable for both small and large servings.

This packaging method is ideal for biscuits that require airtight protection against moisture and air. Common applications of VFFS machines include small portion packs and resealable packaging, popular choices for retail products and convenient on-the-go snacks.

How Does a Biscuit Packing Machine Work?

Biscuit packing machines consist of various parts and mechanisms that work together to package biscuits efficiently. The packaging process generally includes the following steps:

1. Feeding the Biscuits

The machine starts with taking biscuits from a hopper or conveyor. This system keeps a steady flow of biscuits moving into the packaging area.

2. Handling the Packaging Material

The machine uses rolls of film or foil as packaging material. It pulls and positions this material to securely wrap the biscuits.

3. Orienting the Biscuits

Biscuits line up and orient inside the machine. This step keeps the packaging looking good and protects the biscuits.

4. Sealing the Packaging Material

The machine seals the packaging material around the biscuits, creating airtight packs. This sealing process helps keep the biscuits fresh and protects them from outside elements.

5. Cutting the Sealed Packs

After sealing, the machine cuts the wrapped packages into individual packs, making each one ready for distribution.

6. Discharging the Packaged Biscuits

Finally, the packaged biscuits go onto a conveyor belt or packaging line, ready for handling, storage, or shipment.

Factors to Consider When Packaging Biscuits in the Factory

When packaging biscuits, several key factors can make a big difference in the overall success of your product.

Packaging Materials

The choice of packaging materials is critical for keeping biscuits safe from moisture and light. Selecting the right materials, like plastic films or paper-based options, can enhance protection and prolong freshness.

Product Freshness and Protection

Product freshness and protection are essential for customer satisfaction. Quality packaging should effectively create a barrier against air and moisture, ensuring that each biscuit tastes just as good as when it was made.

Portion Control and Size

Consider portion control and size when designing your packaging. Offering a variety of sizes, from single servings to family packs, caters to different consumer preferences and enhances convenience.

Branding and Aesthetics

Branding and aesthetics play a significant role in attracting consumers. An eye-catching design combined with strong branding not only makes your biscuits stand out but also communicates the quality of your product.

Machine Compatibility

Ensuring machine compatibility is vital for a smooth production process. Packaging that works well with your existing machinery can save time and reduce the risk of delays.

Cost-Effectiveness

Assessing cost-effectiveness helps balance quality and budget. It’s important to evaluate the overall costs of materials and production to find a packaging solution that fits your financial goals without sacrificing quality.

Sustainability Considerations

With increasing consumer focus on the environment, considering sustainability is more important than ever. Using biodegradable or recyclable materials can enhance your brand’s appeal to eco-conscious shoppers.

Compliance with Regulations

Finally, compliance with regulations is a necessary step to let your packaging meets food safety standards. This not only helps avoid legal issues but also builds consumer trust in the quality and safety of your biscuits.

Conclusion

Choosing the right packaging for biscuits is vital for freshness, appeal, and compliance in the food industry. With options ranging from plastic films to eco-friendly materials, each type offers unique benefits to meet your needs. At CHLBPACK, we specialize in innovative packing machines tailored for all packaging methods, keeping your biscuits fresh and visually appealing. Ready to enhance your biscuit packaging? Contact CHLBPACK today to discover how we can support your business in achieving packaging excellence!