Hey there! Have you ever wondered how those perfectly sealed packages at the store get that way? You know, the ones that look like they’ve been shrink-wrapped by magic? Well, that’s the magic of heat shrink packing machines. They might not be as famous as the latest tech gadgets, but these machines play a vital role in the packaging industry. Let’s dive into the world of heat shrink wrap machine and uncover what makes them so essential.

What is Heat Shrink Packing Machines?

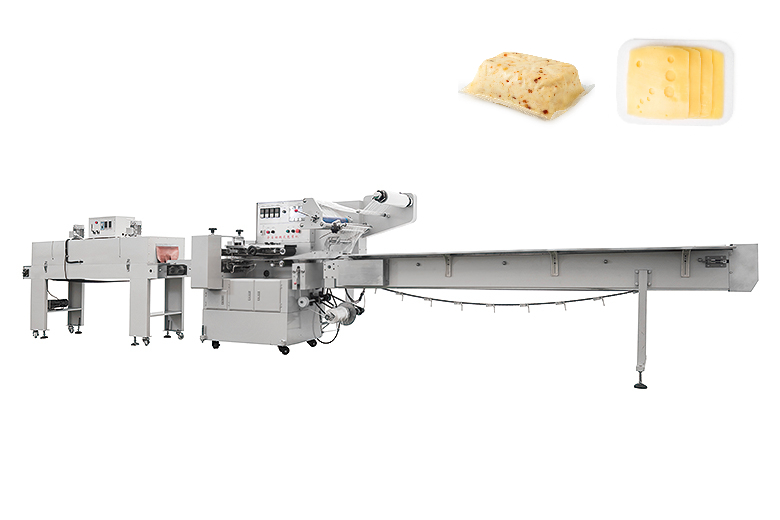

First things first, what exactly is a heat shrink wrap machine? In simple terms, it’s a machine that wraps products in a special plastic film and then applies heat to shrink the film tightly around the product. This process not only keeps the items secure but also makes them look neat and professionally packaged. From food items to electronics, heat shrink packaging machines are used across various industries to ensure products are well-protected and presentable.

How Does a Heat Shrink Packing Machine Work?

Alright, let’s get into the nitty-gritty of how these machines work. Imagine you’re wrapping a gift. You cover it with wrapping paper, fold the edges, and tape it up. Now, picture doing this with a thin plastic film and using heat to make the plastic fit snugly around the item. That’s pretty much what a heat shrink film packaging machine does, but on a much more efficient and industrial scale.

Here’s a step-by-step breakdown:

- Wrapping: The product is first wrapped in a heat-sensitive plastic film.

- Heating: The wrapped product passes through a heat tunnel or under a heat gun, which makes the film shrink.

- Cooling: The film then cools and hardens, forming a tight, protective seal around the product.

Materials Used in Heat Shrink Packing

Not all shrink films are created equal. Different materials are used depending on the packaging needs. Here are the main types:

Polyolefin: The Versatile Choice

Polyolefin is like the Swiss Army knife of shrink films. It’s versatile, durable, and offers excellent clarity, making it perfect for items that need a bit of visual appeal. Plus, it’s food-safe, so it’s often used for packaging food products.

PVC: Cost-Effective and Durable

PVC (Polyvinyl Chloride) is another popular choice. It’s known for its durability and cost-effectiveness. However, it’s not as flexible as polyolefin and can become brittle over time. It’s great for non-food items like DVDs and software boxes.

Polyethylene: Strength and Flexibility

Polyethylene is the heavy-duty option. It’s super strong and flexible, making it ideal for wrapping larger or heavier items. It doesn’t shrink as tightly as polyolefin or PVC but offers excellent protection.

Advantages of Using Heat Shrink Packing Machines

Why should you care about heat shrink wrapper? Well, they bring a ton of benefits to the table:

Enhanced Product Protection

One of the biggest advantages is the protection it offers. The shrink film acts like a second skin, safeguarding products from dust, moisture, and tampering. It’s like putting a protective shield around your items.

Improved Aesthetic Appeal

Presentation matters, right? Shrink wrapping gives products a clean, professional look. It’s all about that first impression, and shrink wrapping helps make a great one by enhancing the product’s visual appeal.

Cost Efficiency in Packaging

Shrink packing is also a cost-effective solution. It reduces the need for bulky packaging materials and can lower shipping costs since it adds minimal weight and volume. Plus, it’s quick and efficient, which means less labor and time spent on packaging.

How to Choose the Right Heat Shrink Packing Machine

Picking the right heat shrink packing machine can feel like finding a needle in a haystack. But don’t worry, here’s a handy guide to help you out:

Product Characteristics

Consider what you’re packaging. Is it frozen food, electronics, or something else? Different products have different packaging needs. Make sure the machine you choose can handle your specific items.

Production Speed and Capacity

How fast do you need to package your products? If you’re running a high-volume operation, you’ll need a machine that can keep up with your production speed and capacity.

Quality and Durability

Invest in a machine that’s built to last. Look for quality construction and reliable performance. A durable machine will save you money in the long run by reducing downtime and maintenance costs.

Cost and ROI

Of course, budget matters. Consider the cost of the machine and the potential return on investment. A more expensive machine might offer better efficiency and lower operating costs, making it a better long-term investment.

Reliable Flow Wrapper Manufacturers or Brands

Lastly, go with a trusted brand. Research a reliable packing machine manufacturer with a solid reputation for quality and customer support. Reliable brands often offer better warranties and service options.

Conclusion

So there you have it, a comprehensive guide to thermal shrink packaging machine. These machines are unsung heroes in the packaging world, offering protection, aesthetic appeal, and cost-efficiency. Whether you’re just getting started with packaging or looking to upgrade your current system, understanding these machines will help you make an informed decision.

FAQs

1. What types of products can be packaged using a heat shrink packing machine?

Industrial heat shrink wrap machine can package a wide range of products, including food items, electronics, books, and household goods.

2. How do I maintain a heat shrink packing machine?

Regular maintenance includes cleaning the machine, checking for wear and tear, and ensuring all moving parts are lubricated and functioning correctly.

3. Can heat shrink packing machines be used for both small and large-scale operations?

Yes, there are various models designed to cater to different scales of operations, from small businesses to large manufacturing plants.

4. Are heat shrink films recyclable?

Some types of shrink films, like polyolefin, are recyclable. Always check the material’s recyclability before disposal.

5. What safety precautions should I take when operating a heat shrink packing machine?

Always follow the manufacturer’s guidelines, wear appropriate safety gear, and ensure the machine is operated in a well-ventilated area to avoid inhaling any fumes.