When it comes to packaging condiments like ketchup, having the right machine for the job is crucial. A ketchup packaging machine is an essential tool for businesses in the food industry, especially those looking to streamline the process of packing ketchup and other sauces into convenient, consumer-friendly packages. These machines offer an efficient, cost-effective, and hygienic way to pack ketchup, ensuring consistent quality across each unit. In diesem Artikel, we’ll explore everything you need to know about ketchup packing machines, including the different types available, how they work, and how to choose the right one for your business.

What is a Ketchup Pouch Packing Machine?

A ketchup pouch packing machine is a specialized device used to fill, seal, and package ketchup into flexible pouches. These pouches are popular for their convenience, lightweight nature, and ability to keep the product fresh for longer. The machine automates the entire process, from the formation of the pouch to the final sealing, ensuring high-speed and consistent sauce pouch packaging.

Typically, these machines are designed to handle a variety of sauces, but they are particularly effective for ketchup, which is often packaged in stand-up pouches or spouted pouches. The machine is equipped with advanced features that control the amount of ketchup dispensed, ensuring that each pouch contains the perfect quantity. The result is a sealed, ready-to-ship product that preserves the integrity of the ketchup and is easy for consumers to handle.

Types of Ketchup Pouch Packing Machines

Choosing the right type of ketchup pouch packing machine is essential for meeting your specific production needs. The two main types of machines used for packing ketchup are Horizontal Form-Fill-Seal (HFFS) and Vertical Form-Fill-Seal (VFFS) Maschinen. Let’s take a closer look at each.

Horizontal Form-Fill-Seal (HFFS) Maschinen

Horizontal Form-Fill-Seal machines are designed to fill pouches in a horizontal motion. These machines are excellent for packing ketchup that requires delicate handling during the filling process. In einer HFFS-Maschine, the packaging material is fed horizontally through the system, where it is shaped into a pouch, filled with ketchup, and then sealed.

This type of machine is typically used for thicker sauces or products that require a more controlled filling process. HFFS machines are suitable for manufacturers who need precision and care during the packaging stage. The horizontal configuration also allows for a larger number of pouches to be processed simultaneously.

Vertical Form-Fill-Seal (VFFS) Maschinen

Auf der anderen Seite, Vertical Form-Fill-Seal machines operate with a vertical packaging film, which is formed into pouches, filled with ketchup, and sealed in a continuous vertical flow. VFFS machines are incredibly fast and efficient, making them a popular choice for businesses looking to increase their production volume.

This type of machine is ideal for businesses that require high-speed production, as VFFS systems can operate at significantly higher speeds compared to horizontal machines. They are also more versatile, as they can accommodate a variety of pouch sizes and types, including stand-up pouches, spouted pouches, and traditional pillow pouches.

Components of Ketchup Pouch Packing Machines

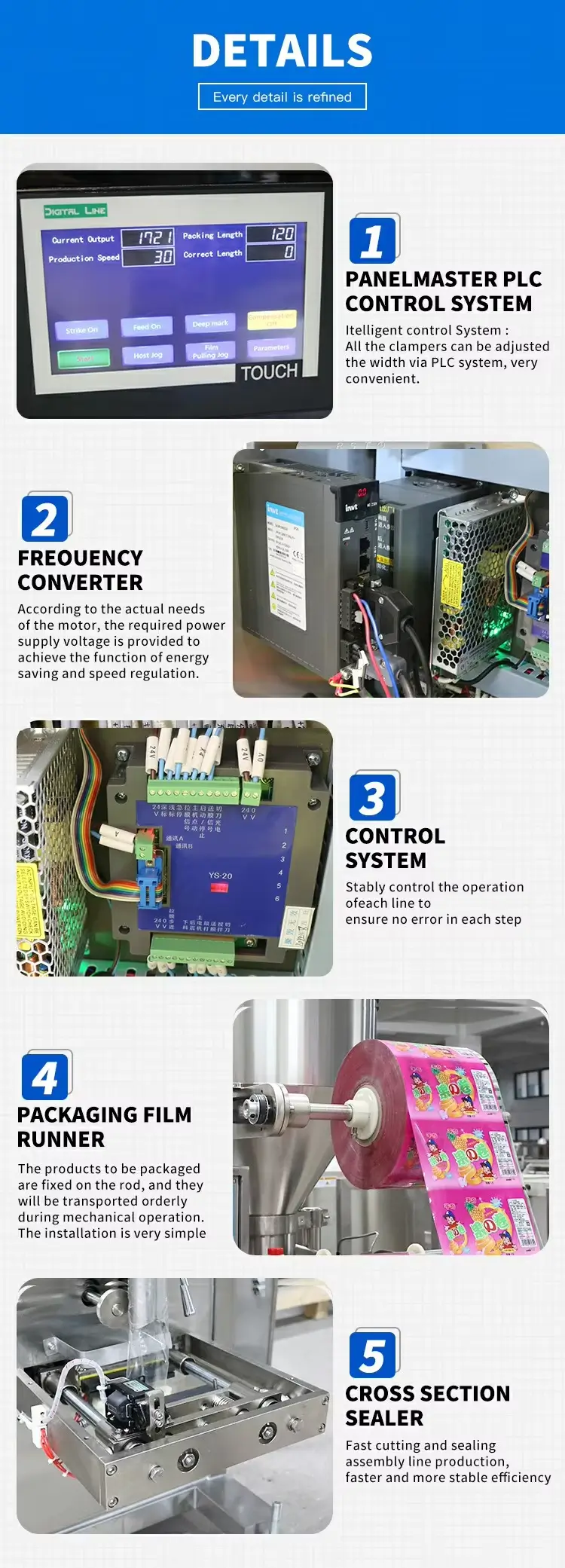

Understanding the key components of a ketchup pouch packing machine will help you appreciate how each part contributes to the efficiency and quality of the final product. Let’s explore the main components.

Füllsystem

The filling system is perhaps the most important component of the machine. It controls the volume of ketchup dispensed into each pouch. This system is designed to handle different viscosities, ensuring that even thicker ketchup is filled without clogging or spilling. The filling system typically uses either piston fillers, pump fillers, or auger fillers to measure and dispense the ketchup into the pouches.

Sealing Mechanism

The sealing mechanism ensures that the pouches are closed tightly after they are filled. This is essential for preserving the freshness of the ketchup and preventing leakage. The sealing process can involve heat sealing or pressure sealing, depending on the machine. In the case of heat sealing, the machine uses heat to fuse the edges of the pouch together, while pressure sealing involves applying pressure to seal the pouch.

A well-functioning sealing mechanism ensures that the ketchup is safely contained within the pouch, prolonging shelf life and maintaining the product’s integrity.

Packaging Material Handling

Packaging material handling systems ensure that the pouches are consistently fed into the machine and aligned correctly. This system is responsible for pulling the packaging film, cutting it to the correct size, and moving it through the machine for filling and sealing. It also helps with adjusting the film tension to avoid jams or misalignments during the process.

How Do Ketchup Pouch Packing Machines Work?

Now that we’ve discussed the components, let’s take a look at how these machines work. The process can be broken down into four main stages: pouch formation, filling the pouch, sealing the pouch, and labeling and coding.

1. Pouch Formation

The first step in the process is the formation of the pouch. Packaging film is pulled through the machine and shaped into a tube. The machine then forms the tube into individual pouches by sealing the edges together, creating a bottom seal.

2. Filling the Pouch

Once the pouch is formed, the ketchup is dispensed into the pouch through the filling system. This stage is crucial for ensuring that the correct amount of ketchup is used, as overfilling or underfilling can result in product wastage or inconsistency.

3. Sealing the Pouch

After the pouch is filled, the next step is sealing. The machine uses either heat or pressure to seal the top of the pouch, ensuring that the ketchup remains fresh and doesn’t leak during transport or storage.

4. Labeling and Coding

Once the pouch is sealed, many machines also include a labeling and coding system that prints important information, such as the expiration date, Chargennummer, and product details, directly onto the packaging. This ensures traceability and provides essential information to consumers.

Benefits of Ketchup Pouch Packaging

Using a ketchup packing machine to package your product offers several advantages over traditional packaging methods. Here are some key benefits.

Efficiency and Speed

Ketchup pouch packing machines can operate at high speeds, packaging hundreds or even thousands of pouches per hour. This level of efficiency is ideal for large-scale production and helps meet high market demand while maintaining consistency.

Consistent Quality

One of the biggest advantages of using an automated packing machine is the consistency in the quality of each pouch. With precise filling systems and reliable sealing mechanisms, every pouch of ketchup will be filled to the same level, ensuring uniformity across all products.

Verlängerte Haltbarkeitsdauer

The proper sealing of the pouch plays a significant role in extending the shelf life of the product. A well-sealed pouch prevents air, Feuchtigkeit, and contaminants from entering, which helps preserve the quality and freshness of the ketchup for longer periods.

Kosteneffektivität

While the initial cost of a tomato ketchup packing machine might seem high, the long-term benefits far outweigh the investment. These machines reduce labor costs, minimize packaging waste, and increase overall efficiency, making them a cost-effective solution for ketchup manufacturers.

How to Choose the Right Ketchup Packing Machine for Your Business

Selecting the right small sauce packaging machine for your business is crucial for ensuring smooth operations and high-quality results. Here are a few factors to consider when making your decision.

Assess Your Production Needs

The first step is to assess your production needs. How much ketchup do you need to package on a daily or weekly basis? If you’re a small business with low production volumes, a smaller, more affordable machine might be sufficient. Auf der anderen Seite, large-scale operations will require a high-speed machine that can handle larger volumes.

Consider Your Packaging Requirements

Think about the type of pouches you need for your product. Stand-up pouches, spouted pouches, and traditional pillow pouches all require different machines. Make sure the machine you choose can accommodate your specific packaging needs.

Evaluating Cost vs. Benefit

While it’s tempting to choose the cheapest option, it’s important to consider the long-term benefits. A higher-quality machine might come with a higher initial cost, but it will offer better durability, faster speeds, and more reliable performance, saving you money in the long run.

Abschluss

A ketchup pouch packing machine is an essential tool for any ketchup manufacturer looking to streamline their production process. Whether you’re packaging small quantities or large volumes, choosing the right machine from a reliable packaging machine manufacturer can save you time, reduce costs, and improve the quality of your product. By understanding the types of machines available, their components,and the benefits they offer, you’ll be better equipped to make an informed decision that suits your business needs.

Investing in the right ketchup packing machine is a step toward enhancing your operational efficiency. It can not only improve your packaging process but also help maintain the quality and freshness of your ketchup. Whether you are running a small-scale operation or a large manufacturing facility, there’s a machine out there that can meet your needs, ensuring your ketchup reaches consumers in perfect condition every time.

FAQs

Are ketchup packing machines easy to maintain?

Ja, most ketchup packing machines are designed for ease of maintenance. They usually come with user manuals that provide detailed instructions for cleaning, troubleshooting, and replacing parts. Regular maintenance, such as cleaning the filling nozzles and inspecting the sealing mechanism, ensures that the machine operates smoothly and minimizes downtime.

How long does it take to install and set up a ketchup packing machine?

The installation time for a tomato ketchup pouch packing machine varies depending on the complexity of the machine and the specific requirements of the production facility. On average, it can take anywhere from a few days to a couple of weeks for installation and testing. Once set up, training for your operators can take additional time to ensure the machine is used properly.

What is the average cost of a ketchup packing machine?

The cost of a sauce packaging machine can vary widely based on factors such as machine type, capacity, features, and the manufacturer. Smaller machines that handle lower volumes can cost anywhere from $10,000 Zu $50,000, while more advanced machines with high-speed capabilities and additional features can range from $100,000 Zu $300,000 or more. It’s important to consider the long-term benefits, including increased efficiency and reduced labor costs, when evaluating the cost of the machine.

Can ketchup packing machines be used for other sauces?

Ja, most ketchup pouch packing machines are versatile and can be used for other sauces such as mustard, mayonnaise, hot sauce, or even dressings. Jedoch, the viscosity and consistency of the sauce might affect the filling system’s performance. It’s important to ensure that the machine you choose can accommodate the different properties of various sauces, including their thickness and flow characteristics.