Kaffeeliebhaber auf der ganzen Welt sind immer auf der Suche nach der perfekten Tasse. Aber in der heutigen schnelllebigen Welt, Bequemlichkeit ist König. Hier kommt die Verpackung von Filterkaffeebeuteln ins Spiel, revolutioniert die Art und Weise, wie Menschen unterwegs frisch gebrühten Kaffee genießen. Und hinter diesem Trend steckt ein Wunder moderner Maschinen: die Tropfkaffeebeutel-Verpackungsmaschine. Ich bin neugierig, was diese Maschine leistet und warum sie für Unternehmen von entscheidender Bedeutung ist? Lassen Sie uns alles aufschlüsseln.

Vorteile einer Kaffee-Tropfbeutel-Verpackung

Was die Verpackung von Kaffeetropfbeuteln so besonders macht? Also, Es geht nicht nur um die Benutzerfreundlichkeit. Lassen Sie uns die wichtigsten Vorteile erkunden.

Frische und Geschmackserhaltung

Wenn Sie über Kaffee sprechen, Frische ist alles, Rechts? Das Letzte, was Sie wollen, ist eine abgestandene Tasse. Die Verpackung von Tropfkaffee ist so konzipiert, dass Geschmack und Aroma erhalten bleiben, Stellen Sie sicher, dass Ihre Kunden ein frisches Produkt erhalten, Jedes Mal ein kräftiges Gebräu. Die Verpackung versiegelt den Kaffee in einem luftdichten Beutel, Konservieren der Bohnen’ natürliche Öle und der frisch geröstete Geschmack bleibt länger erhalten.

Komfort für Verbraucher

Kaffee für unterwegs war noch nie so einfach. Mit Tropfkaffeebeutelverpackung, Alles, was Ihr Kunde braucht, ist heißes Wasser und eine Tasse. Sie können ihren Kaffee überall zubereiten – sei es im Büro, auf einem Campingausflug, oder einfach zu Hause. Dieser Komfort hat dazu geführt, dass Tropfbeutel bei Kaffeeliebhabern, die Qualität nicht zugunsten der Geschwindigkeit opfern möchten, äußerst beliebt sind.

Längere Haltbarkeit

Sie möchten, dass Ihr Produkt monatelang frisch im Regal bleibt? Die Tropfbeutelverpackung verlängert die Haltbarkeit Ihres Kaffees, indem sie Luft und Feuchtigkeit abschließt. Das bedeutet, dass Sie den Kaffee länger aufbewahren können, ohne befürchten zu müssen, dass er seinen Geschmack verliert oder abgestanden wird. Es ist eine Win-Win-Situation für Sie und Ihre Kunden.

Anpassbar für Branding und Marketing

Ihre Markenidentität ist wichtig, Und die Verpackung des Kaffeetropfbeutels bietet eine tolle Präsentationsfläche. Die Außentasche kann vollständig mit Ihrem Logo personalisiert werden, Farben, und Nachrichtenübermittlung. Es ist eine fantastische Gelegenheit, im Regal hervorzustechen und bei den Verbrauchern einen bleibenden Eindruck zu hinterlassen. Plus, Wer liebt nicht schlankes Design?, Markenverpackung?

Was ist eine Tropfkaffeebeutel-Verpackungsmaschine??

Die Tropfkaffeebeutel-Verpackungsmaschine ist das Rückgrat des Filterkaffee-Verpackungsprozesses. Es handelt sich um eine spezielle Maschine, die gemahlenen Kaffee aufnimmt, misst es, und verpackt es in Tropfbeutel, Und das alles unter Gewährleistung von Konsistenz und Effizienz. Ohne diese Maschine, Die Herstellung dieser praktischen kleinen Kaffeepackungen wäre eine manuelle Arbeit, zeitaufwändiger Prozess. Aber damit? Der gesamte Prozess ist rationalisiert, es schneller machen, effizienter, und unglaublich präzise.

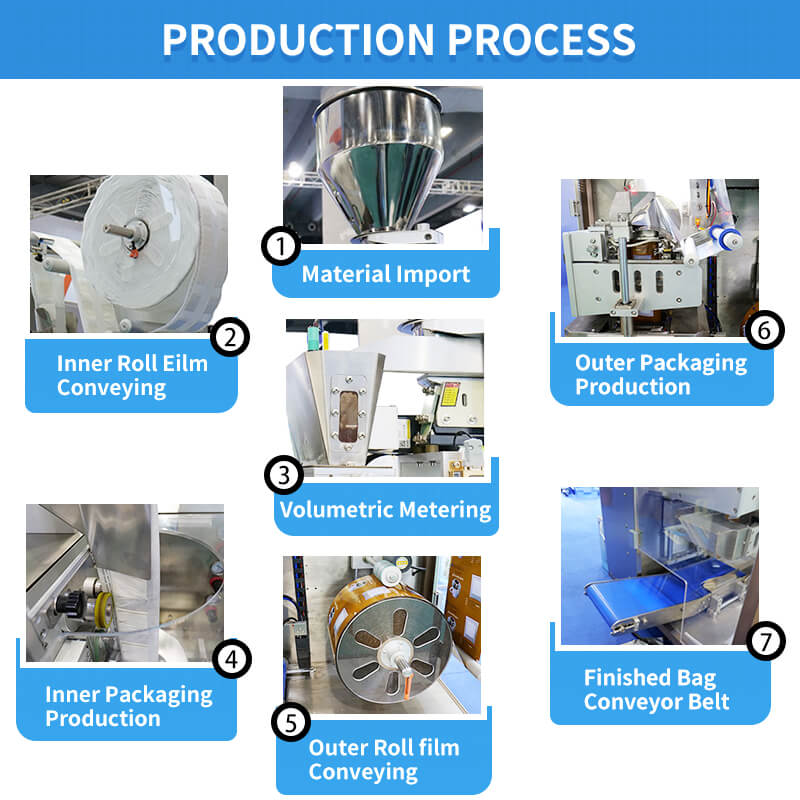

Wie funktioniert eine Tropfkaffeebeutel-Verpackungsmaschine??

Haben Sie sich jemals gefragt, wie diese magischen Maschinen rohen Kaffee verarbeiten und ihn in ordentlich verpackten Kaffee verwandeln?, brühfertiger Beutel? Lassen Sie es uns Schritt für Schritt aufschlüsseln.

Schritt 1: Materialimport

Alles beginnt beim Kaffee selbst. Ein Trichter an der Oberseite der Maschine fasst eine Menge vorgemahlenen Kaffee, welches zur Einspeisung in das System bereit ist.

Schritt 2: Innenrollenfilmförderung

Nächste, Die Tropfkaffee-Verpackungsmaschine zieht eine Filterfolie (der zum Innenbeutel wird) und schickt es an einen Beutelformer. Hier, Die Maschine formt die Folie im Grunde zu einem kleinen inneren Kaffeebeutel, Der Filter, der den Kaffeesatz aufnimmt.

Schritt 3: Volumetrische Messung

Präzision ist hier der Schlüssel. Die Maschine verwendet ein volumetrisches Dosiersystem, um die genaue Kaffeemenge zu messen, die in jeden Beutel gelangt. Die Portionsgrößen müssen angepasst werden? Kein Problem. Die Maschine kann kalibriert werden, um je nach Ihren Anforderungen unterschiedliche Gewichte zu messen.

Schritt 4: Herstellung von Innenbeutelverpackungen

Sobald der Filter geformt ist, wird der Kaffee abgemessen, Es ist Zeit, den Sack zu füllen. Die Maschine füllt den Filterbeutel vorsichtig mit der abgemessenen Kaffeemenge und verschließt ihn. Dieser Schritt stellt sicher, dass der Kaffee frisch bleibt, bis er zum Brühen bereit ist.

Schritt 5: Produktion von Außenbeutelverpackungen

Mit versiegeltem Innenbeutel, Die Filterkaffeebeutel-Verpackungsmaschine geht weiter zum Außenbeutel. Die äußere Folie wird gezogen, geformt, und zur Aufnahme des inneren Filterbeutels vorbereitet. Hier kommen das Branding und das Design ins Spiel – diese äußere Tasche ist das, was der Verbraucher sieht.

Schritt 6: Fertiger Sackförderer (Optional)

Sobald der Innenbeutel in den Außenbeutel eingebettet und versiegelt ist, Das fertige Produkt ist einsatzbereit. Einige Maschinen verfügen optional über ein Fördersystem, das beim Sammeln und Sortieren der fertigen Beutel hilft, Dadurch wird der gesamte Prozess noch effizienter. Sie verpacken Kaffee schneller als je zuvor.

Warum sollten Sie sich für Filterkaffeebeutel-Verpackungsmaschinen für Ihr Unternehmen entscheiden??

Jetzt wissen Sie, wie die Maschine funktioniert, Warum sollte Ihr Unternehmen in eines investieren?? Hier erfahren Sie, warum.

Konsequente Qualitätskontrolle

Einer der größten Vorteile der Verwendung einer Tropfkaffeebeutel-Verpackungsmaschine ist die Konsistenz. Jede einzelne Tüte enthält genau die gleiche Menge Kaffee, auf genau die gleiche Weise versiegelt. Dadurch werden menschliche Fehler vermieden und sichergestellt, dass Ihr Produkt die gleichen hohen Standards erfüllt, Charge für Charge.

Verbesserte Produktionseffizienz

Manuelle Verpackung? NEIN, Danke. Diese Maschinen können Tausende von Kaffeebeuteln in einem Bruchteil der Zeit herstellen, die für die manuelle Herstellung erforderlich wäre. Sie erhöhen Ihre Produktionsgeschwindigkeit, niedrigere Arbeitskosten, und können so leichter mit der Nachfrage Schritt halten.

Niedrigere Verpackungskosten

Effizienz bedeutet Einsparungen. Durch die Automatisierung des Prozesses, Sie sparen Geld für Arbeit und Material, Dies führt zu niedrigeren Gesamtverpackungskosten. Es handelt sich um eine Vorabinvestition, die sich auf lange Sicht auszahlt.

Abschluss

Also, Da haben Sie es – ein tiefer Einblick in die Welt der Tropfkaffeebeutel-Verpackungsmaschinen. Ganz gleich, ob Sie die Effizienz verbessern möchten, garantieren Konsistenz, oder senken Sie Ihre Kosten, Die Investition in eine dieser Maschinen kann Ihren Kaffeeverpackungsprozess verbessern. Plus, mit der wachsenden Beliebtheit von Tropfbeutelverpackungen, Sie bleiben den Verbrauchertrends immer einen Schritt voraus und liefern gleichzeitig ein qualitativ hochwertiges Produkt. Am Ende, Die Filterkaffee-Verpackungsmaschine ist eine kluge Wahl für jedes Unternehmen, das Wert auf Qualität legt, Geschwindigkeit, und Flexibilität.

FAQs zur Filterkaffeebeutel-Verpackungsmaschine

1. Wie schnell kann eine Tropfkaffeebeutel-Verpackungsmaschine Beutel produzieren??

CHLB Filterkaffee-Verpackungsmaschinen können überall produzieren 3,600 Zu 4,800 Säcke pro Stunde, je nach Modell und Einstellungen.

2. Kann die Maschine verschiedene Kaffeebeutelgrößen verarbeiten??

Ja! Bei den meisten Tropfkaffee-Verpackungsmaschinen können Sie die Beutelgröße und das Kaffeegewicht anpassen, Das gibt Ihnen Flexibilität in der Produktion.

3. Ist für meinen Verpackungsprozess ein Fördersystem notwendig??

Während optional, Ein fertiges Beutelfördersystem kann Ihren Arbeitsablauf erheblich beschleunigen und die Verwaltung von Großserienproduktionen erleichtern.

4. Kann ich die Außenverpackung für das Branding individuell anpassen??

Absolut! Mit der Verpackungsmaschine für Tropfkaffeebeutel können Sie den Außenbeutel vollständig mit dem Logo Ihrer Marke personalisieren, Farben, und Nachrichtenübermittlung.

5. Welche Kaffeesorte kann ich in einer Tropfkaffeebeutel-Verpackungsmaschine verwenden??

Es kann jeder vorgemahlene Kaffee verwendet werden, sofern es mit den Einstellungen der Maschine kompatibel ist. Sie können sogar mit Mischungen und Geschmacksrichtungen experimentieren!