Gefrorene Lebensmittelverpackung ist entscheidend für die Erhaltung, schützen, und Vermarktung einer breiten Palette von Lebensmitteln. Von Obst und Gemüse bis zu Fleisch, Meeresfrüchte, und Convenience Foods, Die Verpackung spielt eine Schlüsselrolle bei der Aufrechterhaltung von Qualität und Sicherheit. In diesem Ratgeber, Wir werden die Bedeutung von gefrorenen Lebensmittelverpackungen untersuchen, Typen verfügbar, Schlüsselüberlegungen, und Schritte für benutzerdefinierte Verpackungen für kleine Unternehmen. Tauchen Sie mit uns in die Welt der gefrorenen Lebensmittelverpackungen ein.

Warum Verpackung für gefrorene Lebensmittel?

Verpackung für Tiefkühlkost ist entscheidend für Frische, Schutz, Bequemlichkeit, Sicherheit, und Marketing, Gewährleistung von Qualität und Attraktivität in der Lebensmittelindustrie.

Erhaltung

Einer der Hauptgründe für die Verpackung von gefrorenen Lebensmitteln ist die Erhaltung. Die richtige Verpackung hilft, die Qualität aufrechtzuerhalten, Geschmack, und Nährstoffe der Lebensmittelprodukte über einen längeren Zeitraum. Es verhindert, dass der Gefrierschrank und Gefriergerüche den Geschmack und die Textur des Essens beeinflussen.

Schutz

Gefrorene Lebensmittelverpackungen bieten Schutz vor externen Elementen wie Feuchtigkeit, Licht, und Luft, Dies kann die Qualität des Lebensmittels beeinträchtigen. Es verhindert auch Kontamination und Verderb, Sicherstellen, dass das Essen für den Konsum sicher ist.

Bequemlichkeit

Die Verpackung spielt eine entscheidende Rolle bei der Bequemlichkeit der Verbraucher. Es ermöglicht eine Portionskontrolle, Einfacher Speicher, und mühelose Wiedererwärmung von gefrorenen Lebensmitteln. Bequeme Verpackungsdesigns können die allgemeine Benutzererfahrung und Zufriedenheit verbessern.

Sicherheit

Verpackung für gefrorene Lebensmittel sorgt für Sicherheit, indem sie eine Barriere gegen schädliche Bakterien und Verunreinigungen bereitstellen. Es hält auch die Lebensmittelprodukte während des Transports und der Handhabung sicher, Reduzierung des Risikos einer Kontamination oder des Verderbs.

Marketing

Die Verpackung dient als Werkzeug für Marketing- und Branding -Frozen -Lebensmittelprodukte. Auffällige Designs, Logos, und Etiketten können Verbraucher anziehen und wesentliche Informationen wie Zutaten kommunizieren, Nährwert, und Kochanweisungen. Gut gestaltete Verpackungen können dazu beitragen, Produkte in den Regalen zu unterscheiden und den Umsatz zu steigern.

Welche Lebensmittelprodukte sind normalerweise gefroren?

Obst und Gemüse

Eine Vielzahl von Obst und Gemüse ist gefroren, um ihre Frische und Nährstoffe zu erhalten. Von Beeren und Mangos bis hin zu Erbsen und Mais, Gefrorenes Obst und Gemüse bieten Komfort und ganzjährige Verfügbarkeit.

Fleisch und Geflügel

Fleisch- und Geflügelprodukte wie Hühnchen, Rindfleisch, Schweinefleisch, und die Türkei werden üblicherweise für eine langfristige Lagerung eingefroren. Die richtige Verpackung hilft, die Qualität und den Geschmack dieser proteinreichen Lebensmittel aufrechtzuerhalten.

Meeresfrüchte

Fisch, Garnele, Jakobsmuschel, und andere Meeresfrüchte werden oft eingefroren, um ihre Haltbarkeit zu verlängern und ihre empfindlichen Texturen zu bewahren. Die Verpackung spielt eine wichtige Rolle beim Schutz von Meeresfrüchten vor dem Gefrierschrank und Verunreinigung.

Zubereitete Mahlzeiten

Gefrorene Mahlzeiten, einschließlich Lasagnas, Rühren, und Suppen, Bieten Sie Komfort und schnelle Mahlzeitungslösungen an. Die Verpackung für diese Mahlzeiten sollte sicherstellen, dass sie sicher wieder erwärmt werden und ihre Aromen behalten können.

Backwaren

Kekse, Kuchen, Gebäck, und Brot werden oft gefroren, um ihre Frische zu verlängern. Die Verpackung für Backwaren sollte eine Barriere gegen Feuchtigkeit und Luft liefern, um Stelenheit zu verhindern.

Milchprodukte

Eiscreme, Käse, Butter, und Joghurt sind üblicherweise gefrorene Milchprodukte. Die richtige Verpackung hilft, die Textur und den Geschmack dieser Produkte aufrechtzuerhalten und gleichzeitig den Gefrierschrank zu verhindern.

Eiscreme und gefrorene Desserts

Ein Lieblingsgenuss für viele, Eiscreme und gefrorene Desserts erfordern Verpackungen, die niedrige Temperaturen standhalten und Kristallisation verhindern können. Auffällige Verpackungsdesigns können Kunden anziehen und die Attraktivität des Produkts verbessern.

Fertiggerichte

Gefrorene Komfort Lebensmittel wie Pizzas, Burritos, und Nuggets bieten schnelle und einfache Mahlzeitenoptionen. Die Verpackung für diese Lebensmittel sollte sicherstellen, dass sie bequem gekocht oder wieder erwärmt werden können.

Arten von Tiefkühlkostverpackungen

Im Folgenden sind verschiedene Arten von gefrorenen Lebensmittelverpackungen aufgeführt, die unterschiedliche Vorteile wie Haltbarkeit bieten, Bequemlichkeit, und Nachhaltigkeit, um die vielfältigen Bedürfnisse von gefrorenen Lebensmitteln gerecht zu werden.

Flexible Plastikbeutel

Flexible Plastikbeutel sind leicht, dauerhaft, und vielseitige Verpackungsoptionen für gefrorene Lebensmittel. Sie sind leicht zu lagern, tragen, und offen, Sie ideal für Ein-Service-Portionen.

Pappkartons

Kartonkästen bieten robuste Verpackungen für gefrorene Lebensmittel und werden häufig für den Versand und die Lagerung verwendet. Sie können mit Branding und Kennzeichnung angepasst werden, um Kunden anzulocken.

Aluminiumfolienbehälter

Aluminiumfolienbehälter sind hitzebeständig, recycelbar, und geeignet für den Gebrauch von Ofen und Mikrowellen. Sie eignen sich ideal für gefrorene Mahlzeiten, bei denen das Aufwärmen erforderlich ist.

Starre Plastikbehälter

Starren Plastikbehältern bieten Haltbarkeit und Schutz für gefrorene Lebensmittel. Sie kommen in verschiedenen Formen und Größen, Dadurch sind sie für eine breite Produktpalette geeignet.

Vakuumversiegelte Taschen

Vakuumversiegelte Beutel tragen dazu bei, die Haltbarkeit von gefrorenen Lebensmitteln durch Entfernen von Luft und Verhinderung der Oxidation zu verlängern. Gefrorene Lebensmittelverpackungsbeutel sind ideal für Produkte, für die langfristige Lagerung erforderlich ist.

Plastikschalen mit Plastikfilm

Plastikschalen mit Plastikfilm liefern eine Barriere gegen Feuchtigkeit und Luft, Aufrechterhaltung der Frische von gefrorenen Lebensmitteln. Sie werden üblicherweise für vorverpackte Mahlzeiten und Snacks verwendet.

Standbodenbeutel

Stand-up-Beutel sind bequeme Verpackungsoptionen, die in den Regalen aufrecht stehen. Sie sind leicht, tragbar, und anpassbar, sie ideal für den Verbrauch am Go-Go.

Ziploc -Taschen

Ziploc -Taschen sind wiederverschließbare und wiederverwendbare Verpackungslösungen für gefrorene Lebensmittel. Sie sind bequem für die Portionskontrolle und -aufbewahrung im Gefrierschrank.

Scheibenkartons

Diskussionskartons sind nachhaltige Verpackungsoptionen aus recycelbaren Materialien. Sie sind leicht, umweltfreundlich, und für eine Vielzahl von gefrorenen Lebensmitteln geeignet.

Wesentliche Überlegungen bei der Auswahl der gefrorenen Lebensmittelverpackung

Sauerstoffbarriereigenschaften

Die Verpackung mit hervorragenden Sauerstoffbarriereneigenschaften hilft, Oxidation zu verhindern, Dies kann zu Off-Flavodern und dem Verderb von gefrorenen Lebensmitteln führen. Es ist wichtig, die Qualität und die Haltbarkeit von Produkten aufrechtzuerhalten.

Feuchtigkeitsbeständigkeit

Verpackung, die Feuchtigkeitsbeständigkeit bietet. Es sollte vor Kondensation und Eisbildung schützen.

Gefrierträgige Materialien

Die Auswahl von Free-Safe-Materialien ist unerlässlich, um sicherzustellen, dass die Verpackung niedrigen Temperaturen standhalten kann, ohne zu knacken oder spröde zu werden. Es sollte langlebig und flexibel sein, um Gefrieren und Auftauen aufzunehmen.

Umweltauswirkungen

In Anbetracht der Umweltauswirkungen der Verpackung ist in der heutigen umweltbewussten Welt von entscheidender Bedeutung. Die Entscheidung für nachhaltige und recycelbare Materialien kann Abfall reduzieren und den CO2 -Fußabdruck von gefrorenen Lebensmitteln minimieren.

Mikrowellenverträgliche Bequemlichkeit

Verpackung, die mikrowellensicher und bequem zum Aufwärmen ist, wird von Verbrauchern bevorzugt, die nach schnellen Mahlzeiten suchen. Es sollte ein einfaches Kochen und Speicher ermöglichen, Verbesserung der gesamten Benutzererfahrung.

Kosten

Die Ausgleich von Kosten für die Verpackungsqualität ist für kleine Unternehmen von wesentlicher Bedeutung. Die Entscheidung für kostengünstige und dauerhafte Verpackungslösungen kann dazu beitragen, die Kosten zu senken und gleichzeitig die Produktintegrität sicherzustellen.

Schritte zur maßgefertigten gefrorenen Lebensmittelverpackung für kleine Unternehmen

1. Definieren Sie Ihre Verpackungsanforderungen

Identifizieren Sie zunächst Ihre spezifischen Verpackungsbedürfnisse, einschließlich Produktkompatibilität, Größe, Design, und Markenanforderungen. Berücksichtigen Sie die Speicherbedingungen, Verbraucherpräferenzen, und Budgetbeschränkungen.

2. Erforschen Sie einen Verpackungshersteller

Erkunden Sie verschiedene Verpackungshersteller und Lieferanten, um einen Partner zu finden, der Ihre Anforderungen erfüllen kann. Suchen Sie nach Fachwissen in gefrorener Lebensmittelverpackung, Qualitätszertifizierungen, Kundenbewertungen, und kostengünstige Lösungen.

3. Entwickeln Sie ein Verpackungskonzept

Arbeiten Sie mit Designern und Verpackungsexperten zusammen, um ein Konzept zu entwickeln, das mit Ihrer Markenidentität und Ihren Produktangeboten übereinstimmt. Betrachten Sie die visuelle Anziehungskraft, Funktionalität, Nachhaltigkeit, und regulatorische Einhaltung des Entwurfsprozesses.

4. Wählen Sie Verpackungsmaterialien

Wählen Sie geeignete Verpackungsmaterialien basierend auf der Art der gefrorenen Lebensmittel, die Sie anbieten. Betrachten Sie Faktoren wie Feuchtigkeitsbeständigkeit, Gefrierträgige Eigenschaften, Mikrowellenkompatibilität, und Recyclingabilität.

5. Kostenüberlegungen bewerten

Vergleichen Sie Preisoptionen verschiedener Lieferanten, um die kostengünstigsten Verpackungslösungen für Ihr kleines Unternehmen zu ermitteln. Suchen Sie nach Volumenrabatten, Materialeinsparungen, und Verpackungseffizienz zur Optimierung der Kosten.

6. Testen Sie die Verpackung

Führen Sie gründliche Tests der Verpackung durch, um ihre Kompatibilität mit gefrorenen Lebensmitteln zu gewährleisten. Bewerten Sie seine Leistung beim Einfrieren, Lagerung, Transport, und Handhabung, um potenzielle Probleme oder Verbesserungen zu identifizieren.

7. Eine Bestellung aufgeben

Sobald Sie mit dem Verpackungsdesign und der Leistung zufrieden sind, Bestellen Sie beim ausgewählten Hersteller eine Bestellung. Sicherstellen Sie eine klare Kommunikation, rechtzeitige Lieferung, und Qualitätssicherung, um Ihre kundenspezifische gefrorene Lebensmittelverpackung erfolgreich zu starten.

CHLB: Bieten Sie die hochwertige Lebensmittelverpackungsmaschine an

Als a Hersteller professioneller Verpackungsmaschinen, CHLB bietet eine Reihe hochwertiger gefrorener Lebensmittelverpackungsmaschinen, die den spezifischen Anforderungen der gefrorenen Lebensmittelindustrie entsprechen. Das Folgende ist eine Reihe von CHLB -Maschine.

Vorgefertigte Beutelfüllmaschine

Chlb bietet an Vorgefertigte Beutelfüllmaschinen das sind effizient, zuverlässig, und für verschiedene gefrorene Lebensmittel anpassbar. Diese Maschinen können Beutel mit Präzision und Geschwindigkeit füllen und versiegeln, Gewährleistung der Produktintegrität und Effizienz.

Frischhaltefolien-Verpackungsmaschine

Der Fleckenverpackungsmaschine von CHLB ist ideal, um gefrorene Lebensmittel sicher und bequem zu wickeln. Es bietet eine enge Dichtung, um Lecks und Kontamination zu vermeiden, Verbesserung der Frische und der Haltbarkeit von Produkten.

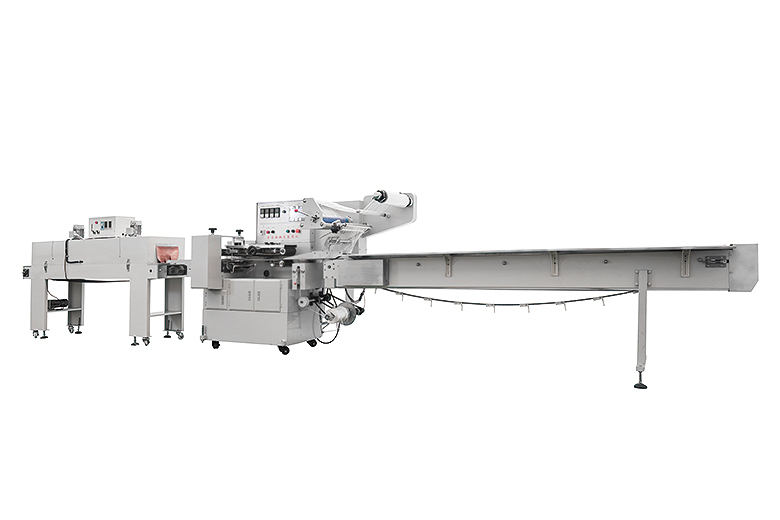

Schrumpffolienmaschine

CLBs Wickelmaschine schrumpfen ist für Verpackungen gefrorener Lebensmittel im Schrumpffilm zum Schutz und zur Präsentation ausgelegt. Es ermöglicht eine schnelle und einheitliche Verpackung, Produkte in den Regalen ansprechend und professionell aussehen.

Abschluss

Abschließend, Gefrorene Lebensmittelverpackung spielt eine entscheidende Rolle bei der Erhaltung, schützen, und eine breite Palette von Lebensmitteln zu fördern. Egal, ob Sie ein Verbraucher sind, der nach bequemen gefrorenen Mahlzeiten oder ein kleines Unternehmen sucht Benutzerdefinierte Verpackungslösungen, Durch die Partnerschaft mit Experten wie CHLB können Sie eine hochwertige und effiziente Verpackung für Ihre gefrorenen Lebensmittel erzielen. Also, Umfassen Sie die Welt der gefrorenen Lebensmittelverpackungen und erhöhen Sie Ihre Produkte auf neue Höhen des Erfolgs und der Zufriedenheit.