Die richtigen Verpackungsmaschinen können den Unterschied in der Lebensmittelindustrie ausmachen. Geben Sie ThermoForming -Verpackungsmaschinen ein - eine vielseitige Lösung, die die Verpackung von Lebensmitteln verändert. Bei diesen Maschinen geht es nicht nur um Bequemlichkeit; Sie bieten eine Reihe von Vorteilen, die die Effizienz und Produktqualität Ihres Unternehmens verbessern können. Also, Warum sollten Sie in Betracht ziehen, in eine Thermoformierung für Lebensmittelverpackungen zu investieren? Lassen Sie uns eintauchen!

Thermoforming verstehen

Der Prozess erklärte

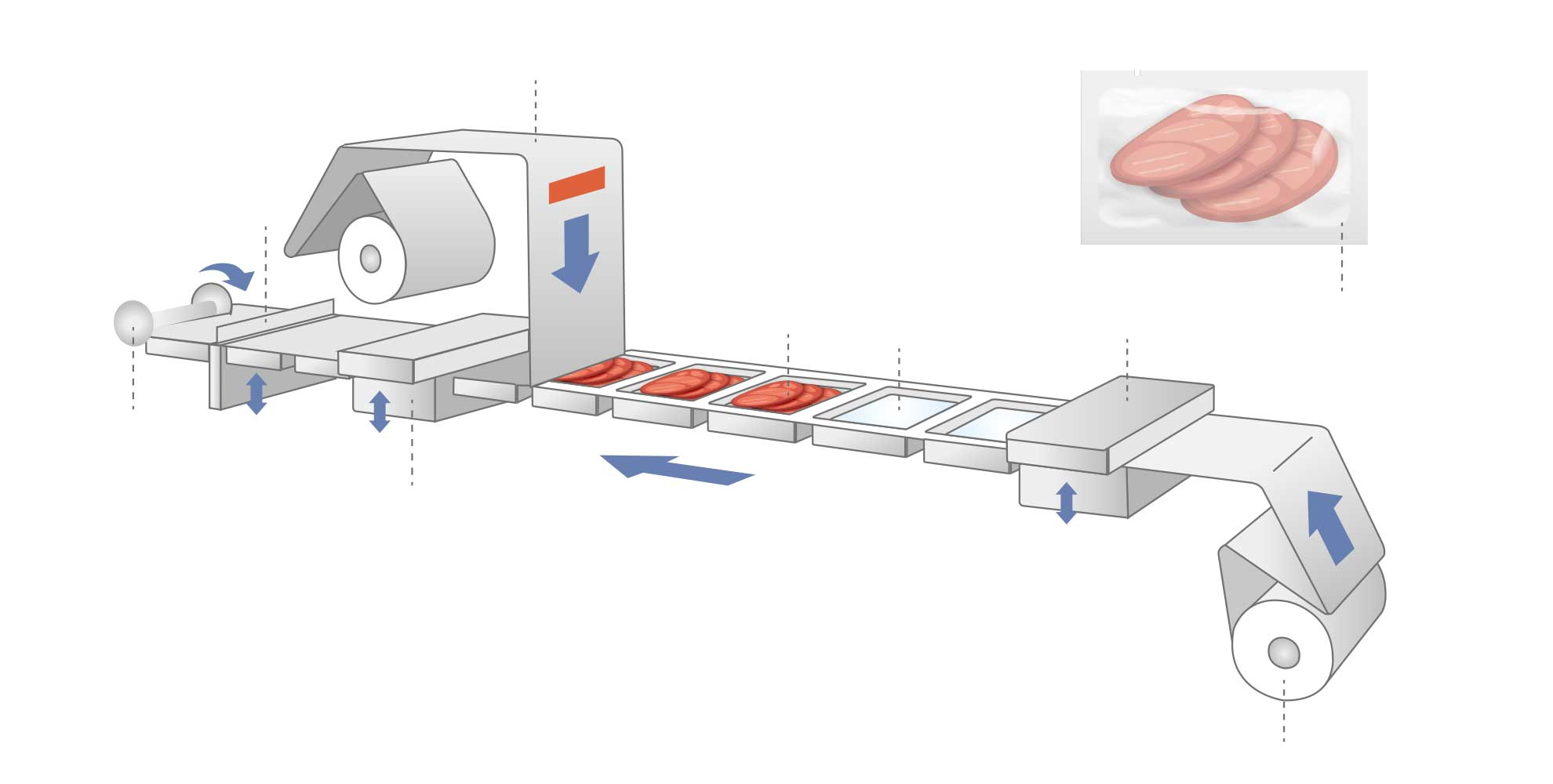

Beim Thermoforming geht es darum, Kunststoffblätter zu erhitzen, bis sie biegsam werden, Dann formen Sie sie mit Formen in bestimmte Formen. Stellen Sie sich das vor: ein flaches Blatt Kunststoff, genau richtig geheizt, dann in eine Form gedrückt, die es zu einem Tablett formt, Tasse, oder Behälter. Es ist wie ein Kuchen zu backen - Sie brauchen die richtige Temperatur und Schimmel, um das perfekte Ergebnis zu erzielen!

Materialien, die bei der Thermoformierung verwendet werden

Tiefziehverpackungsmaschine verwendet in der Regel Materialien wie Haustier, PVC, und Polystyrol. Diese Kunststoffe sind bevorzugt, weil sie leicht sind, dauerhaft, und bieten große Barriereneigenschaften an, Halten Sie Ihr Essen frisch und sicher vor äußeren Verunreinigungen. Also, Wenn Sie darüber nachdenken, Ihre köstlichen Produkte zu verpacken, Betrachten Sie die Materialien, die sie in Bestform halten werden.

Vorteile der Thermoformierung für Lebensmittelverpackungen

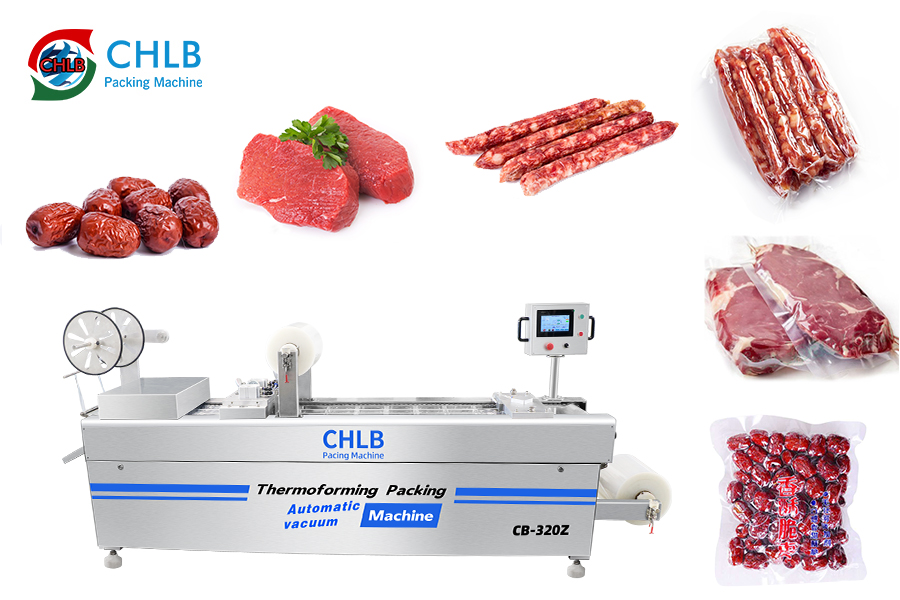

Eines der herausragenden Merkmale der Thermoformierung ist die Anpassungsfähigkeit. Egal, ob Sie verpackt sind Snacks, Früchte, oder zubereitete Mahlzeiten, Diese Maschinen können auf Ihre Bedürfnisse zugeschnitten werden. Mit Optionen zum Anpassen von Größen und Formen, Sie können Verpackungen erstellen, die nicht nur Ihre Produkte schützen, sondern auch Ihre Marke effektiv präsentiert.

Vorteile von Thermoforming -Maschinen für Lebensmittelverpackungen

1. Verbesserter Produktschutz

Stellen Sie sich Ihre Lebensmittelprodukte in stabiler Verpackung vor, Schutzbehälter. Verpackungsmaschinen Thermoformierung erzeugen Verpackungen mit hervorragenden Barriereeigenschaften, die sich gegen Feuchtigkeit und Sauerstoff schützen, Stellen Sie sicher, dass Ihre Produkte frisch bleiben. Plus, Die Wirkungsfestigkeit von thermoformierten Paketen bedeutet während des Transports weniger Bruch-eine Win-Win-Situation für Sie und Ihre Kunden!

2. Verlängerte Haltbarkeitsdauer

Die Reduzierung des Verderbs hat oberste Priorität in Lebensmittelverpackung, und Thermoforming -Maschinen in diesem Bereich hervorrufen. Durch dicht versiegeln, Sie erhalten Frische und verlängern die Haltbarkeit, Lassen Sie Ihre Lebensmittel länger in den Regalen bleiben, ohne die Qualität zu beeinträchtigen. Weniger Abfall bedeutet mehr Gewinne - was das nicht wollen würde?

3. Vielseitigkeit und Anpassung

Einer der größten Vorteile der Thermoformierung ist seine Vielseitigkeit. Sie können eine Vielzahl von Formen und Größen produzieren, die auf verschiedene Produkte zugeschnitten sind, von Einzel-Service-Behältern bis zu größeren Tabletts. Plus, Mit der Möglichkeit, Designs direkt auf der Verpackung zu drucken, Sie können Branding- und Marketingmöglichkeiten verbessern. Ihre Verpackung kann so einzigartig sein wie Ihr Produkt!

4. Effizienz und Kosteneffizienz

Lassen Sie uns über Effizienz sprechen. Thermoformierungsmaschinen sind für die Automatisierung ausgelegt, erheblich steigende Produktivität. Dies bedeutet weniger manuelle Arbeit und reduzierte Betriebskosten. Zusätzlich, Sie erzeugen weniger materielle Abfälle, sie zu einer nachhaltigen und umweltfreundlichen Wahl für Ihre Lebensmittelverpackungsbedürfnisse machen. Es ist eine kluge Investition für das umweltbewusste Geschäft!

5. Einhaltung der Vorschriften zur Lebensmittelsicherheit

Lebensmittelsicherheit ist nicht verhandelbar, und Thermoforming -Verpackungsmaschinen helfen Ihnen dabei, die Branchenvorschriften zu entsprechen. Sie produzieren luftdichte Dichtungen, die Verunreinigungen verhindern, Stellen Sie sicher, dass Ihre Produkte die Gesundheitsstandards entsprechen. Dies schützt nicht nur Verbraucher, sondern steigert auch den Ruf Ihrer Marke.

6. Arbeitskräfteintensität reduzieren

Vorbei sind die Tage übermäßiger manueller Arbeit! Thermoformierungspackmaschinen optimieren den Verpackungsprozess, minimal praktische Beteiligung erfordern. Die Betreiber laden Produkte hauptsächlich in die Tabletts, Während die Maschine den Rest umgeht. Diese Effizienz verringert die Arbeitsintensität, Befreie dein Team für andere wichtige Aufgaben.

Auswahl der richtigen Thermoformmaschine

Produktionsvolumen

Bevor Sie in eine Thermoformierungspackmaschine investieren, Betrachten Sie Ihr Produktionsvolumen. Sind Sie ein kleines Startup oder ein etabliertes Unternehmen mit hohen Produktionsanforderungen? Wenn Sie Ihre Anforderungen verstehen.

Produktgröße und -form

Überlegen Sie sich die Arten von Produkten, die Sie verpackt werden. Unterschiedliche Maschinen sind unterschiedliche Größen und Formen, Stellen Sie also sicher, dass die von Ihnen ausgewählte Maschine Ihre spezifischen Produkte aufnehmen kann. Das Letzte, was Sie wollen, ist ein Missverhältnis, das Ihre Produktion verlangsamen könnte.

Materialbedarf

Wie wir bereits diskutiert haben, Unterschiedliche Materialien können bei der Thermoformierung verwendet werden. Stellen Sie sicher, dass Sie eine Maschine wählen, die mit den Kunststoffen, die Sie verwenden möchten. Diese Kompatibilität ist wichtig, um die gewünschte Qualität und Haltbarkeit in Ihrer Verpackung zu erreichen.

Budget und ROI

Seien wir ehrlich - kostende Angelegenheiten! Legen Sie ein Budget für Ihre Thermoformierung von Vakuumverpackungsmaschine ein und bestimmen Sie Ihre Optionen gegen potenzielle Return on Investment (ROI). Eine teurere Maschine bietet möglicherweise fortschrittliche Funktionen, die die Effizienz verbessern und Abfall verringern, Letztendlich auf lange Sicht Geld einsparen.

Ruf des Herstellers

Endlich, Machen Sie Ihre Hausaufgaben im Hersteller von Thermoforming -Maschinen. Suchen Sie nach Unternehmen mit einem soliden Ruf für Qualität und Zuverlässigkeit. Ein vertrauenswürdiger Verpackungsmaschinenhersteller wird fortlaufende Unterstützung bieten, Wartung, und Zugang zu Ersatzteilen, Stellen Sie sicher, dass Ihre Maschine für die kommenden Jahre reibungslos verläuft.

Abschluss

Investitionen in Thermoforming -Maschinen für Lebensmittelverpackungen sind eine intelligente Wahl für Unternehmen, die die Effizienz verbessern möchten, Produktschutz, und Einhaltung der Sicherheitsvorschriften. Mit ihrer Vielseitigkeit und Kosteneffizienz, Diese Maschinen sind so eingestellt, dass Sie Ihren Verpackungsprozess verändern und Ihrem Lebensmittelgeschäft helfen können. Warum also warten?? Tauchen Sie in die Welt der Thermoformierung ein und erhöhen Sie Ihr Verpackungsspiel!

FAQs

Was sind die unterschiedlichen Thermoformenmaterialien??

Die Thermoformierung verwendet typischerweise Materialien wie Haustier, PVC, und Polystyrol, die für ihre Haltbarkeit und Schutzeigenschaften bekannt sind.

Wie kann ich einen Thermoforming -Maschinenlieferanten finden??

Beginnen Sie mit der Online -Recherche, Überprüfung der Branchenforen, und fragen nach Empfehlungen anderer Lebensmittelunternehmen, um seriöse Lieferanten zu finden.

Was kostet eine Thermoformierung Maschine??

Die Kosten können je nach Funktionen und Funktionen der Maschine stark variieren, Es ist also am besten, Zitate von mehreren Herstellern zu vergleichen.

Sind Thermoformierungsmaschinen einfach zu bedienen?

Die meisten modernen Thermoformierungsmaschinen sind für den benutzerfreundlichen Betrieb ausgelegt, häufig mit automatisierten Systemen zur Vereinfachung des Verpackungsprozesses.