Have you ever wondered how those perfectly shaped containers for your favorite snacks or the blister packs for your medicines are made? Also, the answer lies in a fascinating process called thermoforming. Thermoforming packaging machines are incredibly versatile and play a crucial role in various industries, shaping products from food to medical devices and even car parts. Let’s delve deeper into the world of thermoforming and explore its wide-ranging applications.

Was ist eine Thermoforming -Verpackungsmaschine?

Definition and Process

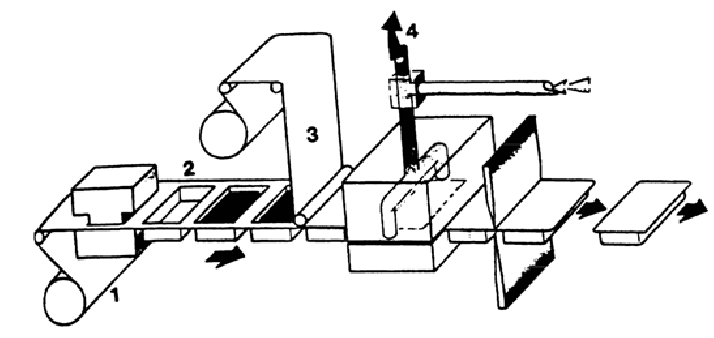

Imagine heating up a thin sheet of plastic, stretching it over a mold, and then using vacuum pressure to create a custom-shaped container. That’s the gist of thermoforming! A Tiefziehverpackungsmaschine is a powerful tool that uses heat and pressure to transform flat plastic sheets into three-dimensional packaging solutions. It’s like a plastic sculptor, creating a variety of shapes and sizes to protect and showcase your products.

Key Components of Thermoforming Packaging Machines

A typical thermoforming machine comprises several key components:

- Heating Element: This element heats the plastic sheet to its forming temperature.

- Mold: The mold provides the desired shape and design to the packaging.

- Vacuum System: The vacuum system draws air out of the heated plastic sheet, pulling it down onto the mold.

- Cooling System: This system cools the formed plastic, solidifying its shape.

- Trimming Unit: The trimming unit removes excess plastic material, creating a finished package.

Food Packaging Industry

Thermoforming reigns supreme in the food packaging industry, shaping a world of deliciousness! From the humble vegetable tray to the enticing seafood package, thermoforming machine for food packaging are everywhere.

Types of Food Products Packaged:

- Gemüse: Think crisp lettuce, colorful bell peppers, and juicy tomatoes – all perfectly presented in thermoformed containers.

- Früchte: From strawberries and blueberries to avocados and mangoes, fruits benefit from the protection and visual appeal of thermoformed packaging.

- Meeresfrüchte: Thermoforming ensures fresh and flavorful seafood reaches your plate, whether it’s delicate salmon fillets or succulent shrimp.

- Grains: Cereal, rice bags, and other grain containers often owe their shape and durability to thermoforming.

Benefits of Thermoformed Packaging:

- Verlängerte Haltbarkeitsdauer: The airtight seal created by thermoforming helps preserve food freshness, extending its shelf life.

- Improved Product Visibility: Thermoformed packaging often features clear windows, allowing consumers to see the product before purchasing.

- Durability and Protection: Thermoformed containers are robust and protect delicate food products from damage.

- Vielseitigkeit: Thermoforming can create diverse shapes and sizes, accommodating various food products and packaging needs.

Medical and Pharmaceutical Industry

Thermoforming also makes its mark in the healthcare world, ensuring the safety and effectiveness of medical devices and pharmaceuticals. Thermoforming packing machine are instrumental in creating blister packs, Tabletts, and other protective packaging solutions for medications, Spritzen, and other medical devices.

Applications in Medical Device Packaging:

- Blister Packs: These packs are commonly used for packaging medications, providing a sterile and tamper-proof environment.

- Trays: Trays are frequently used for organizing and storing medical devices like surgical instruments, catheters, and dressings.

- Protective Clamshells: Thermoforming creates clamshells that securely hold and protect medical devices like inhalers and hearing aids.

Sterility and Safety Considerations:

Thermoforming machines designed for medical applications are often built with features that prioritize sterility and safety:

- Cleanroom Compatibility: The machines are often designed to operate in cleanrooms, minimizing the risk of contamination.

- Sterilizable Materials: Thermoformed medical packaging typically uses materials that can withstand sterilization processes like gamma irradiation or autoclaving.

- Seal Integrity: Thermoforming creates strong, airtight seals to prevent contamination and maintain product integrity.

Consumer Products Industry

From your everyday household items to those unique gifts, thermoforming vacuum packaging machines are shaping how consumer products are packaged.

Packaging for Household Goods:

- Toiletries: Shampoo bottles, soap dispensers, and other toiletries often utilize thermoformed containers for their durability and aesthetic appeal.

- Cleaning Products: Thermoformed containers provide a safe and effective way to package cleaning solutions and detergents.

- Toys: Thermoforming creates durable packaging for toys, ensuring their safety and keeping them organized.

Custom Shapes and Sizes:

Thermoforming offers unparalleled flexibility in creating custom shapes and sizes, enabling manufacturers to tailor packaging to specific product needs and branding requirements.

Automotive Industry

You might be surprised to learn that thermoforming even plays a role in the automotive industry. Thermoforming machine manufacturers create lightweight and durable components used in car interiors and exteriors.

Use in Component Manufacturing:

- Dashboards: Thermoformed dashboards offer a lightweight and aesthetically pleasing solution for car interiors.

- Door Panels: Thermoformed door panels provide a durable and cost-effective option for car exteriors.

- Headliners: Thermoformed headliners are lightweight and acoustically efficient, enhancing the car’s interior.

Lightweighting Benefits:

Thermoformed automotive components contribute to a lighter overall vehicle weight, which translates into improved fuel efficiency and reduced emissions.

Advantages of Thermoforming Machines Across Industries

Thermoforming machines are highly sought after across various industries due to their numerous advantages.

Kosteneffektivität

- Lower Material Costs: Thermoforming often uses less material than other packaging methods, reducing overall material costs.

- Efficient Production Processes: Thermoforming machines can handle high production volumes with minimal labor, improving overall efficiency.

Customization and Flexibility

- Tailored Solutions for Various Applications: Thermoforming allows for the creation of a wide range of shapes, Größen, and designs, making it adaptable to diverse packaging needs.

- Rapid Prototyping Capabilities: Thermoforming enables rapid prototyping, allowing manufacturers to test and refine packaging designs before mass production quickly.

Geschwindigkeit und Effizienz

- Quick Turnaround Times: Thermoforming processes are relatively fast, reducing lead times and getting products to market more quickly.

- High Production Rates: Thermoforming machines can achieve high production rates, Dadurch sind sie für Großverpackungsvorgänge geeignet.

Abschluss

Thermoforming packaging machines are truly versatile and powerful tools, playing a crucial role in shaping the way we package and protect products across various industries. From the food we eat to the medical devices that keep us healthy, thermoforming helps ensure the safety, Qualität, and visual appeal of countless products we encounter every day.

FAQs

1. What types of materials can be used in thermoforming?

A wide variety of plastics can be used in thermoforming, including PVC, HAUSTIER, PP, PS, and ABS. The choice of material depends on the specific application and desired properties like rigidity, clarity, and heat resistance.

2. How does thermoforming compare to injection molding?

Both thermoforming and injection molding are plastic molding processes, but they differ in their applications and methods. Thermoforming is ideal for creating hollow containers and packaging, while injection molding is better suited for solid, three-dimensional parts.

3. What are the key benefits of using thermoforming in food packaging?

Thermoforming offers numerous advantages for food packaging, including extended shelf life, improved product visibility, Haltbarkeit, und Vielseitigkeit. It helps maintain food freshness, protect against damage, and enhance the overall consumer experience.

4. Can thermoforming machines handle large production volumes?

Ja, thermoforming machines are designed to handle high production volumes, making them ideal for large-scale packaging operations. They can efficiently and consistently produce a high volume of thermoformed packages.

5. What are some examples of products made using thermoforming?

Thermoforming is used to create a wide range of products, including food containers, medical device packaging, Blisterpackungen, clamshells, Tabletts, automotive components, und mehr.