In the modern packaging landscape, efficiency and precision are paramount. Premade pouch packing machines have revolutionized the industry, providing a versatile and streamlined solution for various packaging needs. This article delves into the intricacies of these machines, exploring their functions, candidatures, avantages, and key considerations.

What Is a Premade Pouch Packing Machine?

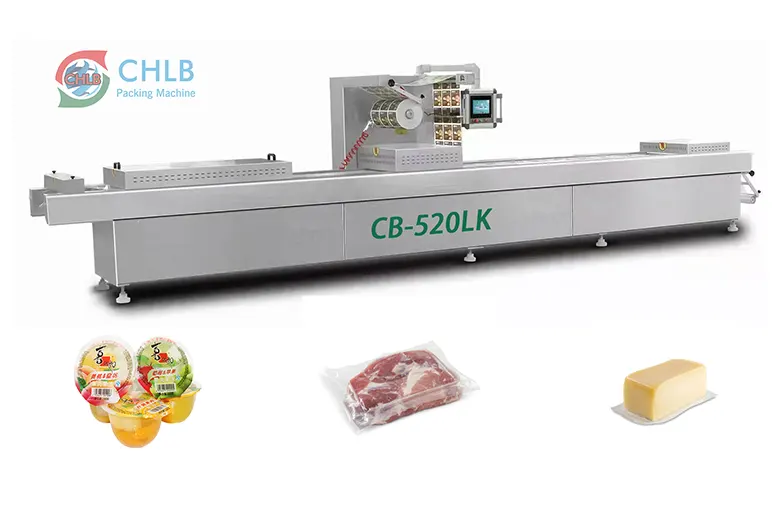

A premade pouch packing machine is an advanced packaging system designed to handle preformed pouches. Unlike traditional packaging machines that create bags from a roll of film, these machines utilize premade pouches, which simplifies the packaging process and enhances efficiency. They are equipped with sophisticated mechanisms to ensure precise filling, scellage, and handling of various pouch types.

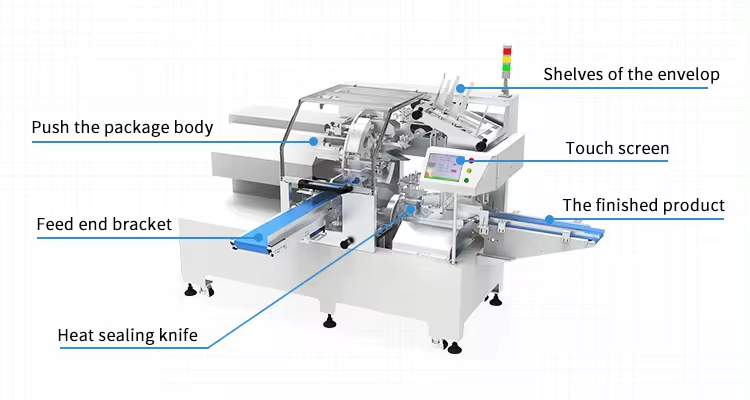

Work Process of Premade Pouch Packing Machine

The operational workflow of a premade pouch packaging machine is a marvel of automation and precision. It involves several key stages to ensure that products are packaged seamlessly and efficiently.

Étape #1: Using Prefabricated Bags

The journey begins with the use of prefabricated bags. These preformed pouches are loaded into the machine, ready to be filled and sealed. This step eliminates the need for forming bags from rolls of film, significantly reducing setup time and material waste.

Étape #2: Fully Automatic Bag Taking

Once the bags are loaded, the machine automatically picks up each bag from the stack. This automated process ensures a consistent and reliable supply of bags, minimizing downtime and human intervention.

Étape #3: Bag Feeding and Opening

The next stage involves feeding the bag into the filling station and opening it. Advanced sensors and mechanical arms work in unison to accurately open each bag, preparing it for the product to be inserted.

Étape #4: Material Pushing

With the bag open and ready, the machine pushes the material into the bag. Whether it’s poudre, liquide, pellets, or any other product, the machine’s precise dispensing system ensures the correct amount is filled into each pouch.

Étape #5: Bag Pushing and Sealing

After filling, the bag is pushed forward to the sealing station. Ici, the machine seals the bag securely, ensuring that the contents are well-protected from external factors. The sealed pouch is then discharged, ready for further processing or shipment.

Application of Premade Pouch Packing Machine

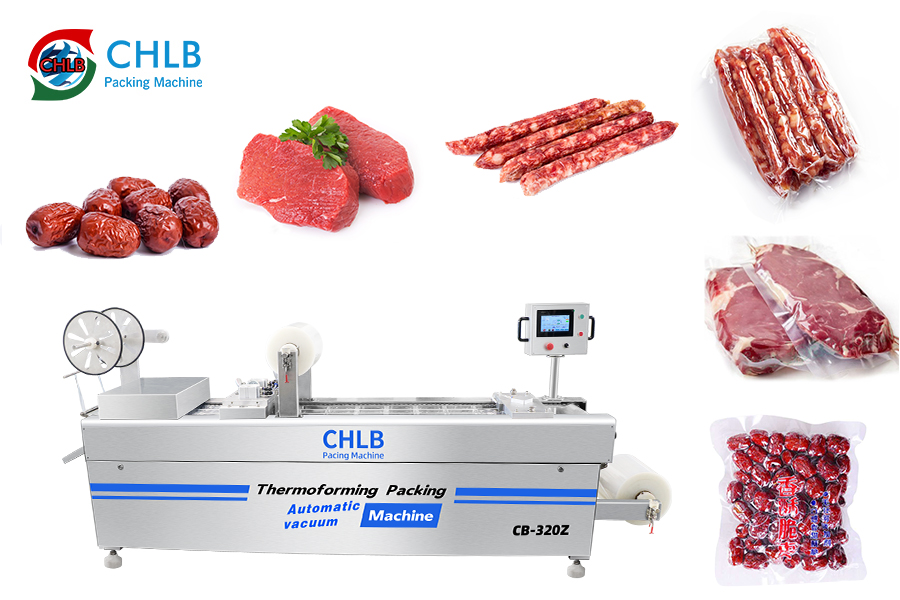

Premade pouch fill and seal machine are versatile and can handle a wide range of products across various industries. Their adaptability makes them an invaluable asset in modern packaging lines.

Poudre & Small Pellets Packaging

From spices and seasonings to pharmaceutical powders, these machines can accurately fill and seal powders and small pellets. Their precision ensures consistent product weights, which is crucial for maintaining quality standards.

Liquide & Paste & Gel Packaging

For liquids, pastes, and gels, premade bag packing machines offer a hygienic and efficient solution. The machines are designed to handle different viscosities, ensuring that each pouch is filled without spills or contamination.

Pet Food Packaging

In the pet food industry, packaging needs to be durable and attractive. Premade pouch fill and seal machine can handle various pet food products, from dry kibble to wet meals, ensuring they are securely packaged and ready for the shelves.

Sock Packaging

Au-delà de la nourriture, these machines are also used for non-food items like socks. They can neatly package pairs of socks in pouches, providing a tidy and appealing presentation for consumers.

Food Packaging

Whether it’s collations, dried fruits, or ready-to-eat meals, premade pouch packing machines excel in the food industry. They maintain the freshness and quality of the food products, extending their shelf life and enhancing consumer satisfaction.

Premade Pouch Packing Machine Bags Types Support

Premade pouch packaging machines are compatible with various types of pouches, each serving different packaging needs and preferences.

Flat Bag

Flat bags are simple and versatile, suitable for a wide range of products. They are easy to handle and store, making them a popular choice for many packaging applications.

Stand-up Pouch

Stand-up pouches are designed with a gusset at the bottom, allowing them to stand upright on store shelves. This type of packaging is excellent for product visibility and branding, making it a favorite in retail environments.

Hang Bag

Hang bags come with a pre-punched hole, enabling them to be hung on display hooks. This packaging type is ideal for small, lightweight products that benefit from vertical display in stores.

Benefits of Using Premade Pouch Packing Machines

Premade pouch packing machines offer numerous advantages, making them a valuable investment for businesses aiming to enhance their packaging operations.

Processus entièrement automatisé

One of the most significant benefits is the fully automated process. These machines handle everything from measuring and picking up bags to filling and sealing, drastically reducing the need for manual labor and increasing production efficiency.

Easy Operation

Despite their advanced capabilities, premade pouch packing machines are designed for easy operation. User-friendly interfaces and intuitive controls allow operators to manage the machines with minimal training, streamlining the workflow.

Unified Packaging

These machines ensure unified and consistent packaging. Every pouch is filled and sealed with the same precision, maintaining a uniform appearance and quality that is essential for brand reputation.

High Stability and Efficiency

Premade pouch packing machines are built for stability and efficiency. They can handle high-speed production without compromising accuracy, making them ideal for large-scale operations where consistency and speed are crucial.

Rentabilité

By reducing material waste and labor costs, these machines offer a cost-effective packaging solution. The efficiency gains and improved productivity translate into significant savings over time, enhancing the overall profitability of packaging operations.

Factors to Consider When Choosing a Premade Pouch Packing Machine

Selecting the right premade pouch packing machine requires careful consideration of several factors to ensure it meets your specific needs.

Capacité de production

Evaluate the production capacity of the machine to ensure it can handle your output requirements. Consider both current and future production needs to avoid bottlenecks as your business grows.

Compatibilité des matériaux d'emballage

Ensure the machine is compatible with the packaging materials you intend to use. Different products may require different types of pouches, and the machine should be versatile enough to handle them all.

Machine Footprint and Layout

Consider the physical footprint of the machine and how it will fit into your production layout. Space constraints and workflow integration are critical factors to ensure smooth operation and maintenance.

Automation Level

Assess the level of automation the machine offers. Higher automation levels can significantly reduce labor costs and increase efficiency, but they may also come with higher upfront costs. Balance these factors based on your operational priorities and budget.

Conclusion

Premade pouch packing machines represent a significant advancement in packaging technology, offering unparalleled efficiency, versatilité, et la rentabilité. En automatisant le processus d'emballage, these machines help businesses maintain product quality, enhance brand presentation, and meet the demands of modern consumers. As the packaging industry continues to evolve, investing in a premade pouch packing machine from a reliable food packaging manufacturer can provide a competitive edge, driving growth and success in a dynamic market.