Tea bag packaging may seem like a simple concept, but there is actually a lot to consider when it comes to choosing the right packaging for your tea. Not all tea bags are created equal, and the packaging plays a crucial role in preserving the quality of the tea, as well as enhancing the overall tea-drinking experience. Dans cet article, we will explore why choosing high-quality tea bags is important, the common materials used in tea bag packaging, the different types of tea bags packaging available, and how tea bags are manufactured using a tea bag packing machine.

Why Choosing High-Quality Tea Bags

High-quality tea bags not only preserves the integrity and freshness of the tea leaves but also enhances the overall tea-drinking experience with convenience, durabilité, and visual appeal.

Preservation of Tea Quality

One of the main reasons why choosing high-quality tea bags is essential is to preserve the quality of the tea itself. High-quality tea bags are designed to protect the tea leaves from exposure to external elements such as moisture, lumière, et de l'air, which can all degrade the flavor and aroma of the tea. By choosing tea bags made from durable materials that provide a tight seal, businesses can ensure that the tea stays fresh and flavorful for longer.

Convenient and Easy to Use

Another benefit of high-quality tea bags is their convenience and ease of use for consumers. Tea bags are a convenient way to enjoy a cup of tea without the hassle of measuring out loose leaves or dealing with messy tea infusers. High-quality tea bags are designed to be sturdy and easy to handle, making them the perfect choice for busy individuals who want a quick and hassle-free tea-drinking experience.

Visually Appealing Packaging

In addition to preserving the quality of the tea, high-quality tea bags also offer visually appealing packaging that enhances the overall tea-drinking experience. Whether it’s a beautifully designed sachet or a unique pyramid bag, the packaging of the tea bag can add a touch of elegance and sophistication to customers’ tea ritual.

Common Materials Used in Tea Bag Packaging

There are different materials used in tea bag packaging, from nylon to silk, mesh, and non-woven fabric. Each material offers unique benefits for preserving the flavor and aroma of your favorite tea blends.

Nylon Tea Bags

Nylon tea bags are one of the most common types of tea bags on the market. They are made from a synthetic material that is strong and durable, allowing for easy brewing without the risk of tearing or bursting. Nylon tea bags are also known for their heat resistance, making them ideal for use with hot water. Cependant, it’s important to note that nylon is not biodegradable, so it may not be the most environmentally friendly option.

Silk Tea Bags

Silk tea bags are a more luxurious option when it comes to tea bag packaging. Made from natural silk fibers, these tea bags are known for their soft texture and elegant appearance. Silk tea bags are also biodegradable, making them a more eco-friendly choice compared to nylon tea bags. The delicate nature of silk tea bags may require more careful handling, but the luxurious feel and aesthetic appeal make them a popular choice among tea connoisseurs.

Mesh Tea Bags

Mesh tea bags are a versatile option that allows for better infusion of the tea leaves. The fine mesh material used in these tea bags allows water to flow through easily, extracting maximum flavor and aroma from the tea leaves. Mesh tea bags are a great choice for loose-leaf teas that require ample room to expand and infuse properly. The transparent nature of mesh tea bags also allows you to see the tea leaves swirling around as they brew, adding a visual element to your tea-drinking experience.

Non-woven Fabric Tea Bags

Non-woven fabric tea bags are another common type of tea bag packaging that offers a balance of strength and permeability. These tea bags are made from a blend of synthetic and natural fibers that are pressed together to create a durable material. Non-woven fabric tea bags provide good filtration while still allowing the tea leaves to expand and release their flavors. The material is also biodegradable, making it a more sustainable option compared to nylon tea bags.

Types of Tea Bag Packaging

The following are some common types od tea bag packaging. From three side seal pouches to mesh bags, each style offers a distinct aesthetic and brewing experience for tea lovers.

Pochette à trois ou quatre côtés scellés

Three or four side seal pouches are a popular choice for tea bag packaging, as they offer a simple and efficient way to package individual tea bags. These pouches are sealed on three or four sides, ensuring that the tea bags are securely enclosed and protected from external elements. Three or four side seal tea bags are a versatile option that can be customized with different shapes, tailles, and designs to suit the needs of the tea brand.

Pyramid Bags

Pyramid tea bags have gained popularity in recent years due to their unique shape and design. These tea bags are made from a mesh material that is molded into a pyramid shape, allowing ample room for the tea leaves to expand and infuse. Pyramid bags are often used for premium teas that require more space to fully release their flavors. The pyramid shape also adds an element of sophistication to the tea-drinking experience, making it a favorite among tea enthusiasts.

Sachets

Sachets are larger tea bags that are designed to hold a single serving of loose-leaf tea. These tea bags are often made from porous materials that allow for better infusion and extraction of flavor. Sachets are a convenient option for those who prefer the flavor of loose-leaf tea but still want the convenience of a tea bag. The spacious design of sachets allows the tea leaves to fully expand, resulting in a richer and more robust flavor profile.

Round Bags

Round tea bags are a classic choice for tea packaging, offering a simple and traditional design. These tea bags are typically made from filter paper or non-woven fabric and are sealed with a round shape. Round bags are easy to use and offer a secure way to brew your favorite tea. While they may not offer as much room for the tea leaves to expand compared to other shapes, round bags are a practical and cost-effective option for everyday tea drinkers.

Mesh Bags

Mesh bags are similar to pyramid bags but are typically made in a rectangular or square shape. These tea bags are made from a fine mesh material that allows for better infusion and extraction of flavor. Mesh bags are a popular choice for herbal teas and other fine loose-leaf teas that require more room to expand during brewing. The transparent nature of mesh bags also allows for a visually appealing tea-drinking experience, as you can watch the tea leaves dance and swirl as they steep.

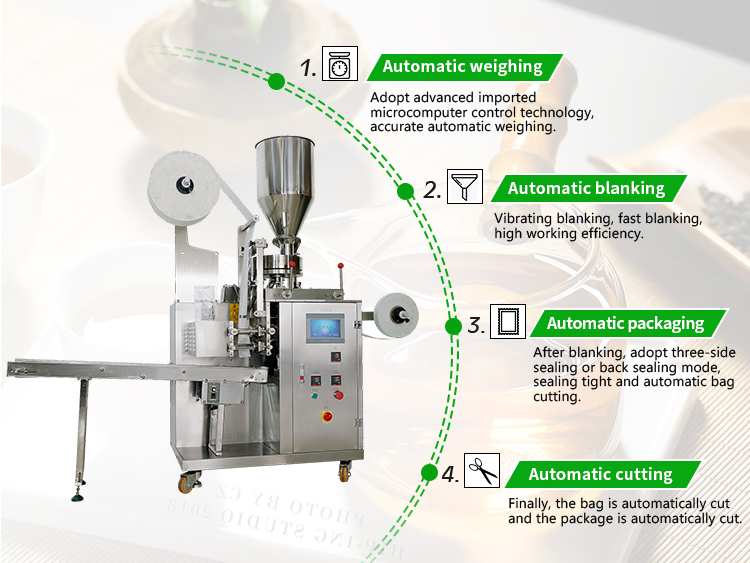

How Are Tea Bags Manufactured by Tea Bag Packing Machine

Learn how automatic tea bag packing machines ensure precision and efficiency in producing high-quality tea bags step-by-step.

Étape 1: Automatic Weighing Tea

The first step in manufacturing tea bags is to accurately weigh the tea leaves to ensure the correct amount is used in each bag. An automatic weighing system is used to measure the precise amount of tea needed for each individual bag. This helps to ensure consistency in flavor and quality across all tea bags produced.

Étape 2: Automatic Blanking

After the tea leaves are weighed, they are blanketed onto the material that will form the tea bag. This process involves laying out the material in a flat sheet and evenly distributing the tea leaves across its surface. Tea bag making machines help to streamline this process and ensure that each tea bag is filled correctly.

Étape 3: Automatic Packaging

Once the tea leaves are blanketed onto the material, the next step is to automatically package the tea bags. The material is folded and sealed to create individual tea bags, with the option to customize the shape and design of the bags based on the desired packaging style. Automatic packaging machines are used to speed up this process and ensure that the tea bags are sealed securely.

Étape 4: Automatic Cutting Tea Bags

After the tea bags are packaged, they are automatically cut to size using precision cutting systems. This ensures that each tea bag is uniform in shape and size, ready to be packaged and distributed to consumers. Automatic tea bag packing machines help to increase efficiency and accuracy in the tea bag manufacturing process, resulting in high-quality tea bags that meet industry standards.

CHLB: Provide High-Quality Tea Bag Packing Machine

CHLB is a leading food packging manufacturer providing high-quality tea bag packing machines that are designed to streamline the tea bag manufacturing process. With a range of innovative machines that offer precision weighing, automatic blanking, packaging, and cutting capabilities, CHLB ensures that tea brands can produce consistent and reliable tea bags with ease. Whether you are looking to package traditional round bags or innovative pyramid bags, CHLB has a solution to meet your tea packaging needs. With a focus on quality, efficacité, et la satisfaction du client, CHLB is the go-to choice for tea bag packing machines.