Se sei coinvolto nella produzione, trasformazione alimentare, o qualsiasi settore che richieda un packaging efficiente e affidabile, Sei nel posto giusto. Le macchine per imballaggi termoformanti sono dispositivi che trasformano i fogli di plastica riscaldati in soluzioni di imballaggio personalizzate. Queste macchine stanno rivoluzionando il modo in cui i prodotti sono confezionati, fornire soluzioni pratiche e innovative. Sia che tu sia curioso di sapere i loro meccanismi interni o che cerchi di investire in uno, Questa guida ti ha coperto!

Cos'è una macchina per l'imballaggio termoformante?

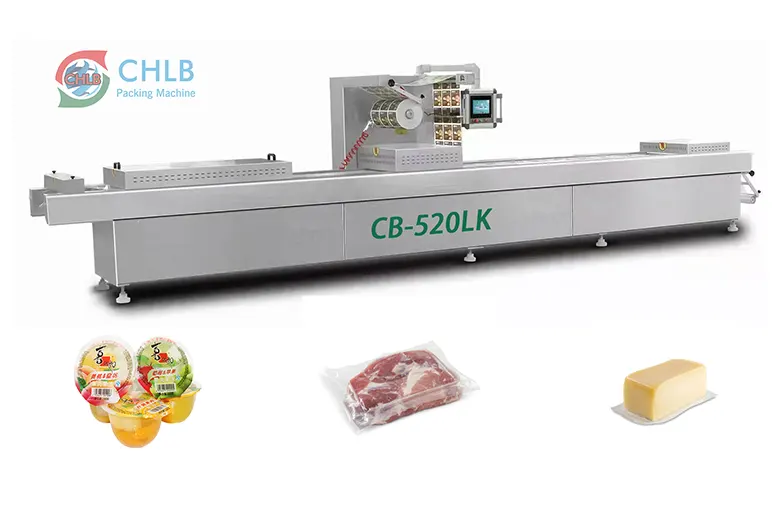

COSÌ, Cos'è esattamente una macchina per l'imballaggio termoformante? Una macchina per termoformi, Spesso indicato come una macchina per l'imballaggio di elasticizzazione, è progettato per Crea imballaggio atmosfera a vuoto o modificato (CARTA GEOGRAFICA). In termini semplici, Trasforma fogli di plastica in pacchetti preformati, come vassoi o contenitori. Il processo prevede il riscaldamento della plastica fino a quando non è flessibile, quindi modellandolo usando uno stampo. Ciò consente la produzione di soluzioni di imballaggio durevoli e personalizzabili per una varietà di prodotti, Dagli alimenti alle forniture mediche. La versatilità delle macchine per termoformi le rende essenziali in molti settori.

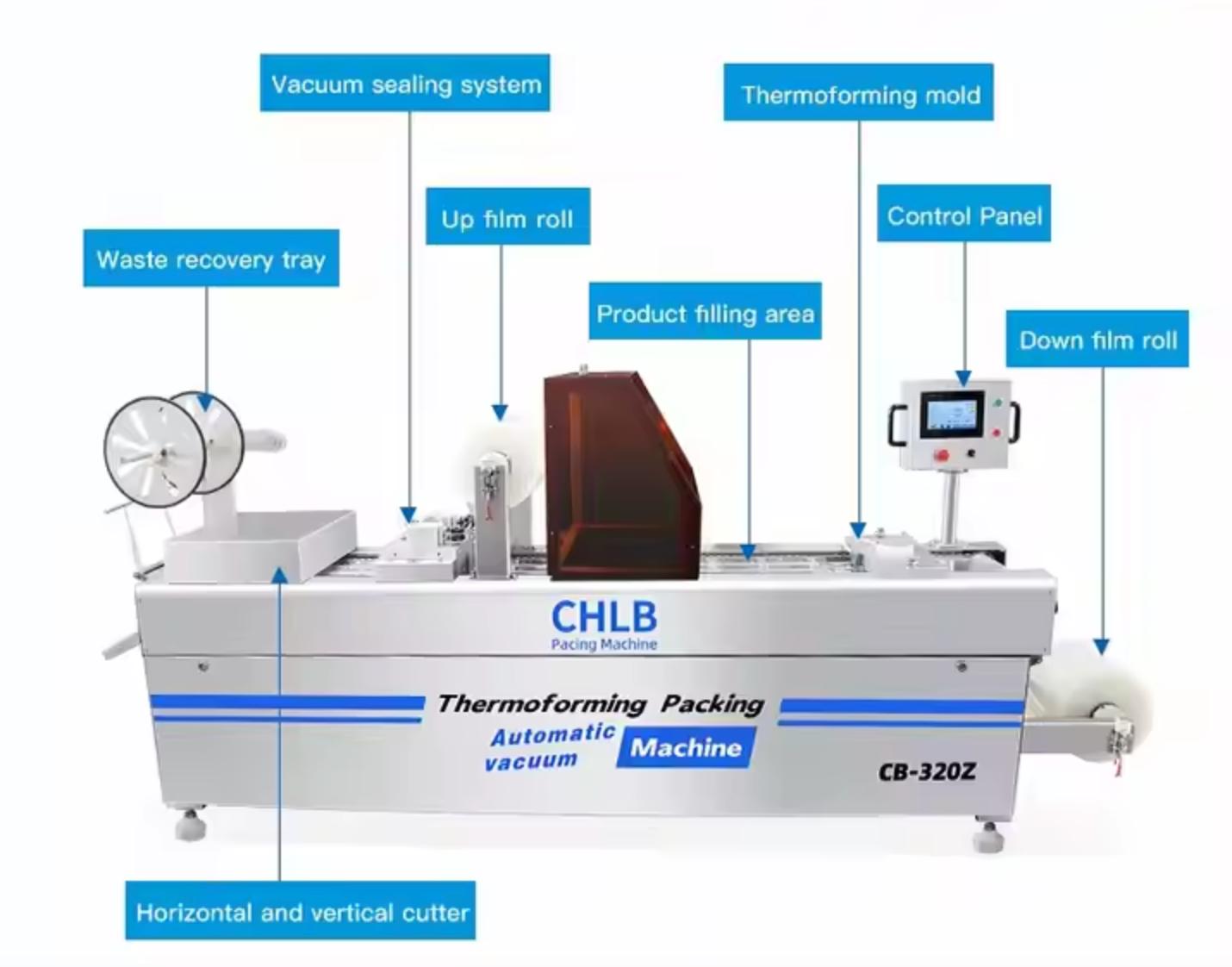

Chiave componenti di una macchina per imballaggi termoformi

Una macchina da imballaggio termica ben progettata presenta diversi componenti critici che garantiscono un funzionamento stabile e affidabile, Grazie a un rigoroso sistema di controllo di qualità. Ecco uno sguardo più da vicino a queste parti essenziali:

1. Roll di film

Questo componente utilizza un freno a polvere magnetica per il rilascio automatico del film e il pre-stretta. Include anche un dispositivo di regolazione del film trasversale di tipo maniglia, consentendo una gestione precisa del film.

2. Pompa a vuoto

Dotato di una pompa a vuoto Busch da 200m3/h ad alte prestazioni dalla Germania, Questo sistema raggiunge una portata di 100-300 m³/HZJ and an ultimate vacuum level of 0.5 Mbar, Garantire un'efficace sigillatura del vuoto.

3. Sistema di controllo

Il sistema di controllo intelligente Siemens V90 PLC presenta un touchscreen di simulazione a colori da 10 pollici. La scatola di controllo a sbalzo rotante in lega in lega in alluminio può ruotare 320 °, rendere operate intuitive ed efficienti.

4. Roll di film su

Alimentato da un servo motore tedesco Siemens, Questo componente offre un posizionamento cinematografico ad alta velocità e ad alta precisione. Incorpora un sistema di tracciamento fotoelettrico americano banner, Completo con una funzione di memoria di spegnimento per una maggiore affidabilità.

5. Stampo termoformante

I nostri stampi sono realizzati in lega combinata in alluminio, Fornire una resistenza ad alta resistenza e corrosione. They can be customized and easily changed, enhancing flexibility in production.

6. Electronics

The machine features top-quality electronics, including components from renowned manufacturers like Siemens (Germany) and Mitsubishi (Giappone), ensuring optimal performance and longevity.

7. Transverse Cutting System

This system employs a single-pole movable and adjustable independent punching mechanism, guaranteeing high-speed, stable, and precise cutting for clean finishes.

8. Waste Recycling

The dual motor design includes a separate waste recycling system, ensuring smooth operation. This feature simplifies disassembly and assembly while maintaining environmental hygiene.

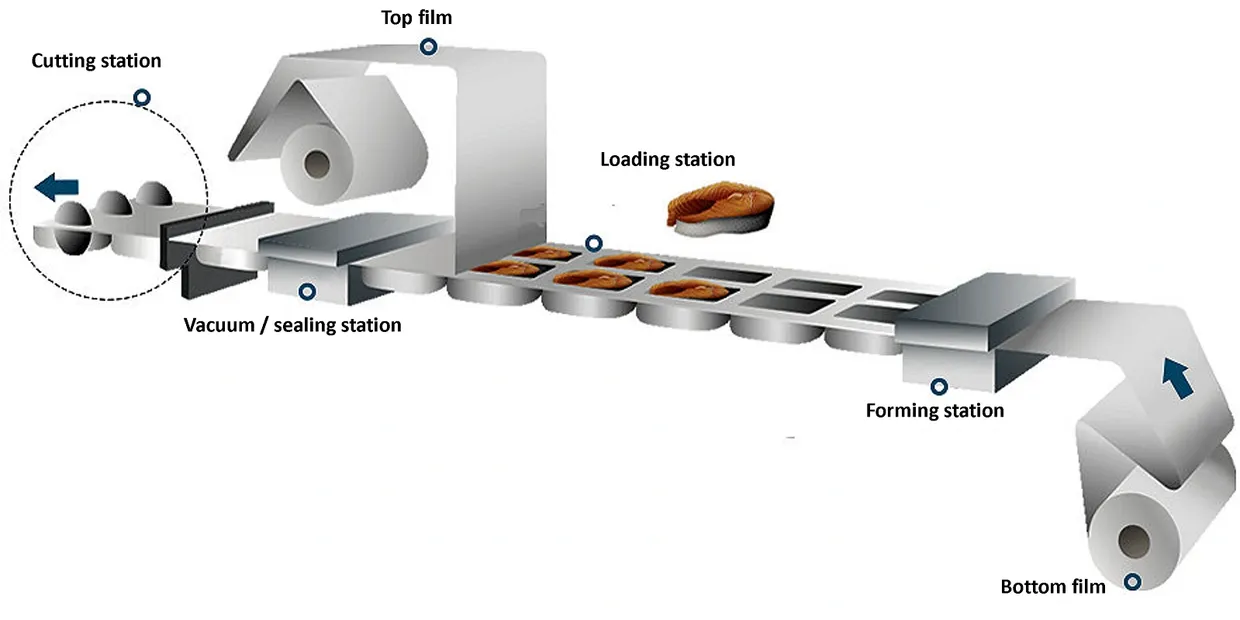

How Thermoforming Packaging Machines Work?

Let’s break down how these machines operate. Primo, the process begins with a plastic sheet, often made from materials like PET or PVC. This sheet is heated until it reaches a soft, workable state. Once it’s pliable, air pressure is applied on both sides of the film, pushing it downward to adhere to the mold and create a unique tray shape. This innovative method completes the packaging forming process quickly and efficiently. Il risultato? Custom-shaped containers that are ready to protect and present your products beautifully.

Benefits of Thermoforming Packaging Machines

Ridurre l'intensità del lavoro

One of the standout benefits of using a thermoforming packing machine is the significant reduction in labor intensity. Traditional packaging methods can be time-consuming and labor-intensive, often requiring multiple workers to manually bag and seal products. In contrast, with a thermoforming machine, the process is largely automated. All you need is someone to place the food into the tray next to the machine—easy, Giusto?

Save Corporate Cost

Investing in a thermoforming packing machine can lead to substantial cost savings for businesses. The high degree of automation means less manpower is required, which translates to lower labor costs. Inoltre, the efficiency of these machines minimizes material waste and production downtime, helping your bottom line.

Versatility in Packaging

Another impressive feature of thermoforming vacuum packaging machines is their versatility. They can handle a wide range of materials and products, from vacuum packaging to inflated packaging. Whether you’re packaging meat, frutti di mare, frutta, or even pharmaceutical products, a thermoforming machine can adapt to your specific needs.

Protezione avanzata del prodotto

Let’s face it: product protection is paramount. Thermoforming packaging provides enhanced protection against external elements, ensuring that your goods stay fresh and undamaged. The tight seals and durable materials used in thermoforming keep moisture, aria, and contaminants at bay, prolonging shelf life and maintaining product integrity.

Applications of Thermoforming Packaging

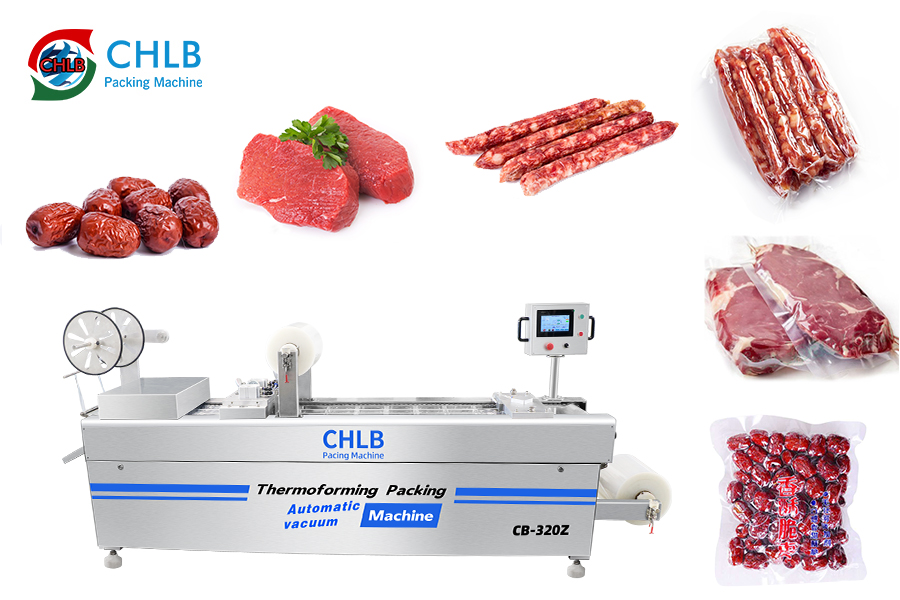

Industria alimentare

A thermoforming machine for imballaggio alimentare is designed to create durable and customizable containers that protect food products while extending their shelf life.

They’re commonly used for packaging meats, frutti di mare, frutta, verdure, e piatti pronti. The ability to create airtight seals means your products stay fresh longer, and their attractive presentation can entice customers.

Medical Industry

Thermoforming packaging isn’t just for food; it’s also crucial in the campo medico. Da blister pacchi per i farmaci ai vassoi per strumenti chirurgici, Queste macchine assicurano che i prodotti medici siano confezionati in modo sicuro.

Beni di consumo

Oltre il cibo e la medicina, Le macchine per termoformi sono utilizzate per l'imballaggio di vari beni di consumo. Pensa ad articoli come componenti hardware o parti elettroniche: il termoformo offre una solida protezione e organizzazione per questi prodotti, rendendo più facile conservare e trasportarli.

Fattori da considerare quando si sceglie una macchina per termoformio

Compatibilità dei materiali

Quando si seleziona una macchina per termoformamento, La compatibilità del materiale è cruciale. Diverse macchine sono specificamente progettate per funzionare con alcuni tipi di materie plastiche, come l'animale, PVC, o polistirene. È essenziale assicurarsi che la macchina che scegli possa gestire efficacemente i materiali che intendi utilizzare, Poiché ciò influisce direttamente sulla qualità e sulle prestazioni della tua confezione.

Requisiti del volume di produzione

Valutare le esigenze del volume di produzione è vitale nel processo decisionale. Stai lanciando una piccola impresa o si sta ridimensionando per la produzione su larga scala? Comprendere i requisiti di output ti aiuterà a scegliere una macchina in grado di tenere efficiente il passo con le tue esigenze di produzione, assicurandoti di soddisfare le aspettative dei clienti senza ritardi.

Considerazioni sullo spazio e sull'installazione

Prima di effettuare un acquisto, Valuta attentamente il tuo spazio di lavoro. Le macchine a termoformio possono variare in modo significativo, Quindi è importante assicurarsi di avere uno spazio adeguato sia per l'installazione che per il funzionamento. Un layout ben pianificato consentirà un flusso di produzione regolare, reducing the risk of accidents or inefficiencies caused by cramped conditions.

Thermoforming Machine Manufacturer Reputation

Infine, conduct thorough research on the manufacturers of thermoforming machines. Opt for un fornitore affidabile di macchine per l'imballaggio with a solid track record in the industry. A reliable manufacturer will not only provide a high-quality machine but also offer essential support, maintenance, and access to spare parts, ensuring your operations run smoothly and efficiently.

Conclusione

Insomma, thermoforming packaging machines are a powerful asset in modern packaging solutions. Their efficiency, versatilità, and ability to enhance product protection make them invaluable across various industries. By understanding how they work and the benefits they offer, you can make an informed decision when choosing the right machine for your needs. Embrace the future of packaging with thermoforming!

Domande frequenti

- What types of products can be packaged with a thermoforming machine? Thermoforming machines can package a variety of products, including food items, forniture mediche, and consumer goods.

- How does a thermoforming vacuum packaging machine differ from traditional methods? Thermoforming vacuum packaging machines automate the sealing process, reducing manual labor and enhancing product freshness.

- What maintenance is required for thermoforming machines? Pulizia regolare, inspection of seals, and ensuring proper lubrication of moving parts are essential for maintaining performance.

- Are plastic thermoforming machines eco-friendly? Many manufacturers are developing eco-friendly materials for thermoforming, such as biodegradable plastics, to reduce environmental impact.

- How does thermoforming improve product shelf life? Le guarnizioni ermetiche create dal termoformio impediscono l'aria e l'umidità, prolungando così la durata di conservazione dei prodotti confezionati.