Scegliere la macchina per l'imballaggio giusta per la tua azienda è un grosso problema. La macchina selezionata influisce su tutto, dalla velocità con cui è possibile confezionare i prodotti sul tipo di imballaggio che puoi utilizzare. Si riduce a due tipi chiave: VFFS (Sigillo di riempimento modulo verticale) e HFFS (Sigillo di riempimento modulo orizzontale) macchine. COSÌ, Come scegli quello che è meglio per te? Ci immerciamo ed esploriamo il mondo delle imballaggi e ti aiutiamo a fare la scelta giusta!

Tabella di confronto: VFFS vs. Macchine HFFS

| Caratteristica | Macchine VFFS | Macchine HFFS |

| Orientamento della macchina | Verticale (pacchetti formati, riempito, e sigillato verticalmente) | Orizzontale (pacchetti formati, riempito, e sigillato in orizzontale) |

| Tipi di prodotto | Meglio per i liquidi, polveri, e prodotti a flusso libero | Ideale per solido, semi-solido, e prodotti di forma irregolare |

| Velocità | Ad alta velocità, soprattutto per i prodotti granulari e liquidi | Più lento ma altamente adattabile a diversi stili di imballaggio |

| Flessibilità dell'imballaggio | Limitato a specifici formati di imballaggio | Più versatile in formati e stili di imballaggio |

| Requisito dello spazio del pavimento | Compatto, occupa meno spazio sul pavimento | Impronta maggiore, richiede più spazio orizzontale |

| Costo | Costo iniziale inferiore, generalmente più conveniente | Più investimenti iniziali a causa della complessità |

| Applicazioni | Cibo & bevanda, prodotti farmaceutici, prodotti chimici | Confetteria, cosmetici, alimenti surgelati |

| Costi di manutenzione | Inferiore, Design della macchina più semplice | Più alto, più complesso con funzionalità personalizzabili |

| Stili di imballaggio | Opzioni di insaccamento standard | Buste personalizzate, vassoi, e altri imballaggi creativi |

Cos'è una macchina per l'imballaggio VFFS?

Una macchina per imballaggi VFFS, o macchina per guarnizione di riempimento in forma verticale, è un pezzo di attrezzatura progettata per formarsi, riempire, e sigilla pacchetti tutti in un movimento verticale. Sembra semplice, Giusto? BENE, C'è un po 'di più.

Come funzionano le macchine VFFS?

Macchina di imballaggio VFFS inizia tirando un rotolo piatto di film. Questo film è modellato in un tubo, sigillato verticalmente lungo il bordo, e poi sigillato in basso. Ora, Ecco la parte divertente: il prodotto (Potrebbe essere qualsiasi cosa, dai fondi di caffè al sapone liquido) viene lasciato cadere in questa borsa dall'alto. Una volta riempita la borsa, La macchina lo sigilla in alto, e voilà: hai un prodotto ben confezionato!

Componenti chiave delle macchine VFFS

Una macchina per l'imballaggio VFFS in genere è costituita da un pulsante del film, formare il colletto, sigillando le mascelle, e un sistema di riempimento del prodotto. Queste parti funzionano in armonia per assicurarsi che le borse siano formate correttamente, riempito a livello giusto, e sigillato saldamente.

Vantaggi delle macchine VFFS

Perché scegliere una macchina VFFS? BENE, Queste macchine sono compatte, efficiente, E soprattutto per l'imballaggio di cose come granuli, polveri, o liquidi. Dal momento che opera verticalmente, Ottiene meno spazio sul pavimento, renderlo un campione di risparmio spaziale per le aziende con strutture più piccole. Più, Se la velocità è il tuo gioco, Le macchine VFFS possono gestire l'imballaggio ad alta velocità, Significa che puoi sfornare prodotti come l'attività di nessuno.

Cos'è una macchina per l'imballaggio HFFS?

La macchina per l'imballaggio HFFS, o macchina orizzontale di riempimento della forma, ha uno stile completamente diverso. Funziona in orizzontale, E quel semplice cambiamento nell'orientamento fa una grande differenza nei tipi di prodotti che gestisce.

Come funzionano le macchine HFFS?

In una macchina HFFS, Il film viene alimentato in orizzontale, A differenza della sua controparte verticale. Il film si muove lungo un trasportatore orizzontale, dove è modellato in buste o pacchetti. I prodotti vengono quindi posizionati nelle buste formate, e dopo quello, La macchina sigilla e taglia i pacchetti. Semplice, Giusto?

Componenti chiave delle macchine HFFS

Una macchina HFFS presenta un trasportatore orizzontale, Alimentatori di prodotto, e strumenti di tenuta. Questa configurazione consente una maneggevolezza del prodotto, Il che è perfetto se stai confezionando oggetti delicati o richiedono un posizionamento preciso.

Vantaggi delle macchine HFFS

Il vantaggio più grande di una macchina per l'imballaggio HFFS è la sua flessibilità. Queste macchine sono ideali per il solido, semi-solido, o anche prodotti di forma irregolare. Pensa alle barrette di caramelle, surgelato, o cosmetici. A differenza della macchina per guarnizione di riempimento verticale, HFFS ti dà una maggiore flessibilità nei tipi di imballaggio che puoi creare. Quindi se stai cercando versatilità, La macchina orizzontale di riempimento della forma è un vincitore.

Differenze tra le macchine VFF e HFFS

Va bene, Ora che sappiamo come funzionano queste macchine, Confrontiamoli testa a testa!

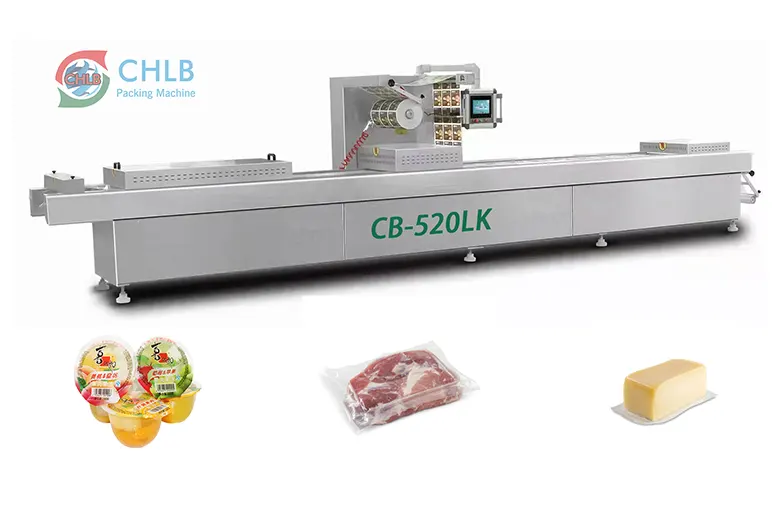

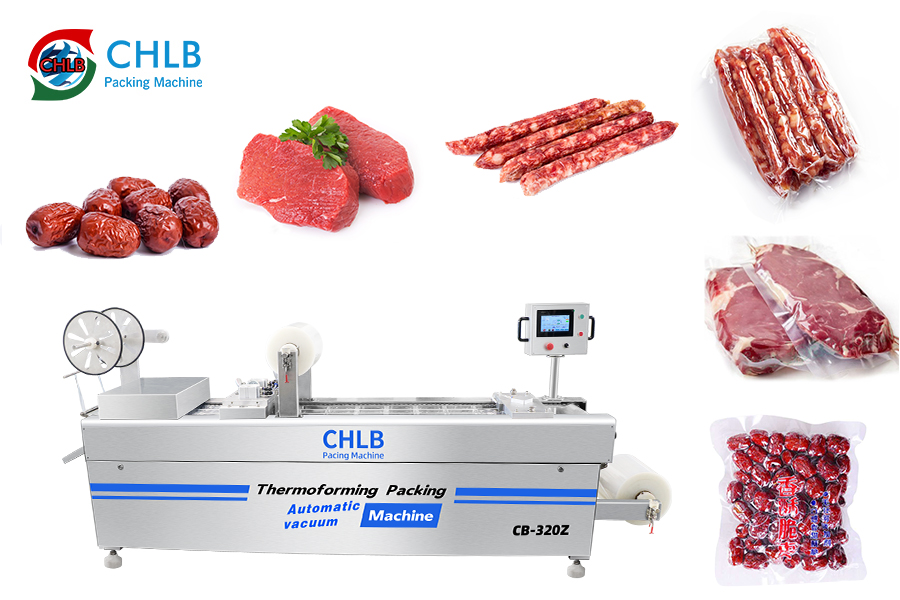

macchina orizzontale di riempimento e sigillatura del modulo

Orientamento della macchina: Verticale vs. Orizzontale

La differenza più ovvia? Orientamento. La macchina per l'imballaggio VFFS funziona in verticale, Mentre la macchina HFFS funziona in orizzontale. Ciò influisce su come i prodotti vengono alimentati e confezionati, e influisce anche i tipi di prodotti che possono gestire in modo efficiente.

Tipi di prodotti confezionati

La macchina VFFS è perfetta per l'imballaggio di prodotti a flusso libero come le polveri, cereali, o liquidi. D'altra parte, La macchina per l'imballaggio HFFS è più adatta per l'imballaggio di articoli solidi e semi-solidi come snack, cioccolatini, o prodotti farmaceutici.

Applicazioni in vari settori

A causa di queste differenze, Le macchine per l'imballaggio VFFS si trovano comunemente in settori come alimenti e bevande, prodotti farmaceutici, e sostanze chimiche. Nel frattempo, L'imballaggio HFFS è ideale per settori come la pasticceria, cosmetici, e cibi congelati. COSÌ, Il settore in cui operi potrebbe facilmente dettare quale macchina è migliore per la tua azienda.

Fattori chiave da considerare quando si sceglie tra VFF e HFFS

Scegliere tra una macchina VFFS e HFFS può essere complicato, Ma se lo suddividi nei fattori chiave che contano di più per la tua attività, La decisione diventa molto più chiara. Diamo un'occhiata più da vicino a ciò che dovresti considerare.

Tipo di prodotto in confezione

La prima cosa a cui pensare è il tipo di prodotto che stai confezionando. Hai a che fare con prodotti a flusso libero come i fondi di caffè, cereali, o liquidi? In tal caso, La macchina per imballaggio VFFS è progettata pensando a te. Eccelle nel gestire questi tipi di materiali. Ma, Se il tuo prodotto è solido, semi-solido, o stranamente modellato, come le barrette di caramelle, spuntini, o cosmetici: la macchina per l'imballaggio HFFS è il tuo go-to. Il suo orientamento orizzontale è perfetto per riempire e sigillare accuratamente oggetti più delicati o irregolari.

| Forma del prodotto & Borsa Tipi | VFFS | HFFS |

| Polvere | ✓ | |

| Liquido | ✓ | |

| Granello | ✓ | |

| Patatine fritte | ✓ | |

| Bastoncini | ✓ | |

| Blocchi regolari | ✓ | |

| Borsa a cuscino | ✓ | ✓ |

| 3-Sigillo laterale | ✓ | |

| 4-Sigillo laterale | ✓ |

Requisiti di velocità e efficienza dell'imballaggio

La velocità è la chiave in qualsiasi linea di imballaggio, Giusto? Le macchine VFFS sono note per i loro tassi di produzione veloci, Soprattutto quando si lavora con liquidi o prodotti granulari. Sono perfetti per le aziende che devono impacchettare rapidamente grandi quantità. Ma se la versatilità è più importante della velocità, Potresti appoggiarti a una macchina HFFS. Anche se potrebbe non impacchettare così velocemente, È altamente adattabile, consentendo una gamma di stili di imballaggio che potrebbero dare al tuo prodotto un vantaggio unico.

Spazio disponibile per pavimenti nella tua struttura

Siamo onesti: lo spazio è spesso limitato negli impianti di produzione, E la dimensione della macchina conta. Se il tuo spazio di lavoro è stretto, Una macchina per guarnizioni di riempimento in forma verticale è probabilmente la soluzione migliore. Il suo design verticale occupa meno spazio sul pavimento, rendendolo ideale per piccole aree di produzione. Sul lato del rovescio della medaglia, Se lo spazio non è un problema e hai bisogno di una macchina in grado di gestire prodotti più grandi o più voluminosi, La macchina orizzontale di riempimento in forma ti darà la flessibilità e la stanza per confezionare prodotti più complessi.

Budget e costi operativi a lungo termine

Il costo è sempre un fattore, Giusto? Generalmente, Le macchine VFFS sono dotate di un prezzo iniziale inferiore rispetto alle macchine HFFS. Ma non dimenticare di considerare i costi a lungo termine, Come il mantenimento e l'utilizzo dell'energia. VFFS Le macchine sono in genere meno complesse, che può portare a minori spese di manutenzione nel tempo. Tuttavia, Se i tuoi prodotti richiedono un packaging più personalizzato, IL Macchina HFFS potrebbe giustificare il suo costo iniziale più elevato con la flessibilità dell'imballaggio e la diversità del prodotto che offre.

MANDATTURANTI’ Reputazione di VFF e macchine HFFS

Finalmente, Pensa a chi sta facendo la tua macchina. Un produttore rispettabile può fare la differenza. Aziende come Bosch e Ishida sono note per le loro macchine VFF affidabili, Offrire prestazioni forti e assistenza clienti. Sul lato HFFS, Marchi come Ulma e Multivac si distinguono. Un solido produttore garantisce non solo una macchina di qualità, ma anche un servizio in corso, Disponibilità delle parti, e supporto: che sono tutti cruciali per mantenere la linea di imballaggio in esecuzione a lungo raggio.

Conclusione

COSÌ, Quale macchina per l'imballaggio è giusto per te: VFFS o HFFS? Tutto dipende dal tuo prodotto, velocità di produzione, e spazio disponibile. Se stai lavorando con i liquidi, polveri, o granuli e hanno spazio limitato, UN macchina confezionatrice vffs Potrebbe essere il tuo go-to. Se hai bisogno di flessibilità di imballaggio per prodotti solidi o semi-solidi, IL macchina orizzontale di riempimento e sigillatura del modulo Potrebbe essere una soluzione migliore. Non importa la tua scelta, Entrambe le macchine possono migliorare il tuo processo di imballaggio e aiutarti ad ampliare la tua attività.

Domande frequenti

1. Le macchine VFFS e HFFS possono utilizzare gli stessi materiali di imballaggio?

SÌ, in molti casi, Entrambe le macchine possono gestire materiali simili come laminati o film in plastica. Tuttavia, La scelta del materiale dipende dal tipo di prodotto da confezionare e dalla tecnologia di tenuta di ciascuna macchina.

2. Quale macchina è più conveniente per le piccole imprese?

Una macchina per l'imballaggio VFFS è generalmente più economica in anticipo e occupa meno spazio, rendendolo un'opzione migliore per le piccole imprese con budget limitati.

3. Quanto tempo ci vuole per passare da un prodotto su queste macchine?

Entrambe le macchine possono passare da un prodotto per i prodotti relativamente rapidamente, Ma le macchine HFFS in genere richiedono più tempo a causa della loro flessibilità e opzioni di imballaggio personalizzate.

4. Può maneggiare i materiali di imballaggio eco-compatibili ecologici?

SÌ! Sia le macchine per l'imballaggio VFFS che HFFS possono essere adattate per utilizzare materiali biodegradabili e riciclabili, A seconda del produttore e dei requisiti del prodotto.

5. Qual è la durata tipica di una macchina VFFS o HFFS?

Con una manutenzione adeguata, Sia le macchine VFFS che HFFS possono durare 10-15 anni o più, rendendoli un investimento a lungo termine per le tue esigenze di imballaggio.