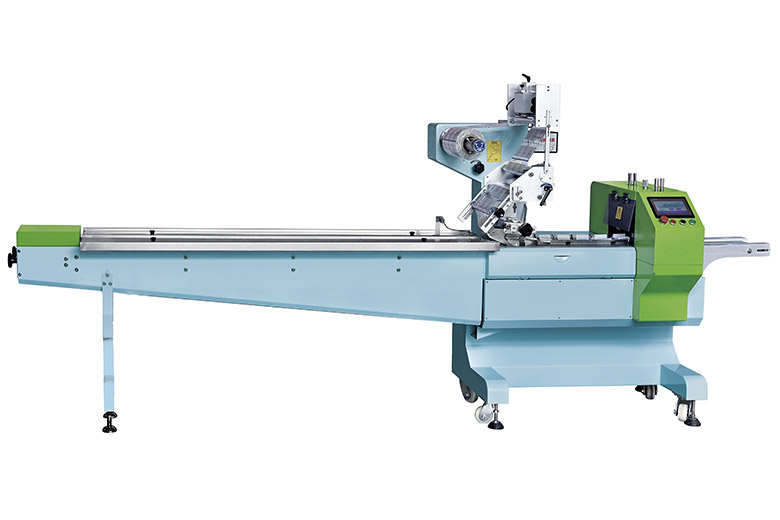

Larghezza massima della pellicola 350 mm(13.78”), adatto per altezza del prodotto inferiore a 55 mm(2.17”), film material support lamilate film.Both belt conveyor and chain conveyor.

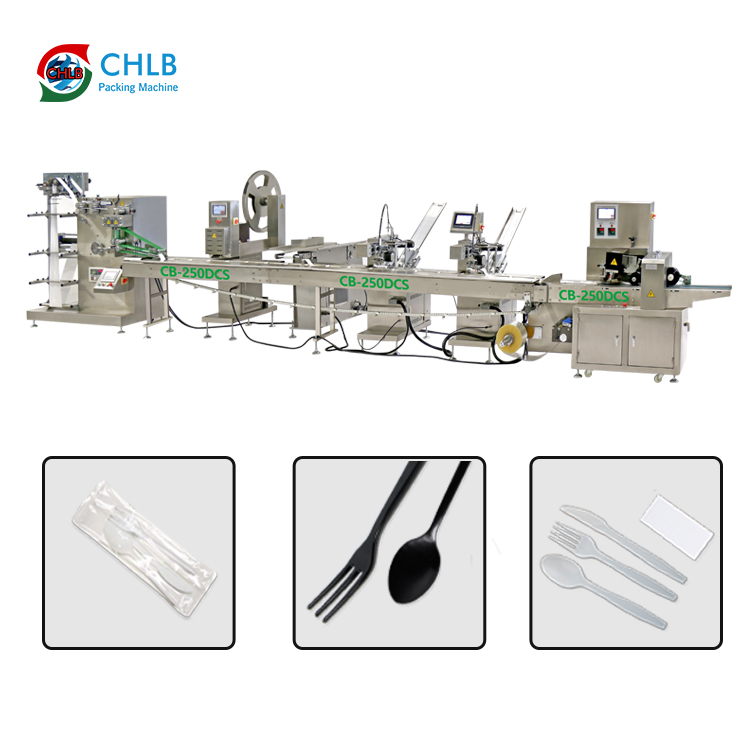

CHLB fornisce macchine confezionatrici professionali per le industrie di tutto il mondo, e il confezionatrice a flusso orizzontale(involucro di flusso) è uno dei più popolari nella nostra lista. In base ai prodotti che devi confezionare, le condizioni della macchina, e la pellicola da imballaggio che stai utilizzando, possiamo personalizzare una soluzione perfetta.

Larghezza massima della pellicola 350 mm(13.78”), adatto per altezza del prodotto inferiore a 55 mm(2.17”), film material support lamilate film.Both belt conveyor and chain conveyor.

300SZ is a flow packing machine specially design for syringe packaging, with a automatic feeding system to archive a max package speed of 200PPM.

Progettazione di un touch screen a sbalzo per un funzionamento conveniente, utilizzando una taglierina box-motion per garantire un'efficace sigillatura della confezione, and employing a pure PE film to save packing material costs. This machine supports a maximum film width of 680mm(26.77”) and a maximum product height of 110mm(4.33”).

Le ganasce box-motion garantiscono una manutenzione semplice e una chiusura ermetica. Supporta film in PE puro per risparmiare sui costi di imballaggio, accommodating a maximum film width of 450mm(17.72”), and enabling a maximum product height of 90mm(3.54”).

The tube packaging machine is specifically engineered for steel tubes and pipes with a maximum length of 6 meters (236 inches). It features an automatic air cylinder-based feeding system and a collection bracket for finished products.

The horizontal flow pack machine features a compact design, accommodating a maximum film width of 350mm. It is suitable for products with a height of max 60mm and can achieve a maximum packaging speed of 200PPM.

Utilizzando materiali di prima qualità e impiegando ingegneri capaci, siamo competenti nel fornire una vasta gamma di macchine confezionatrici flow pack ad alte prestazioni per migliorare l'efficienza del confezionamento esistente, e puoi recuperare rapidamente il costo dell'investimento. Le caratteristiche della nostra macchina Flow Wrap sono le seguenti:

I servomotori di marca controllano con precisione la velocità e il comando di azione.

Induttori precisi, i sistemi di controllo autoregolanti e i pannelli di controllo utente intelligenti garantiscono elevata precisione e facilità d'uso.

Soluzioni di imballaggio automatizzate per risparmiare sui costi di manodopera e migliorare l'efficienza.

Soluzioni di imballaggio automatizzate per risparmiare sui costi di manodopera e migliorare l'efficienza.

Usiamo SUS 304 acciaio inossidabile per soddisfare le esigenze della produzione alimentare, e forniamo un design intuitivo per proteggere il personale operativo.

Food grade stainless steel to ensure hygiene & safety. Puoi scegliere SS304 e SS316 per le parti della macchina.

Veloce, accurato, & customizable according to your needs. Puoi sempre regolare i dettagli sul pannello attrezzato.

HFFS(Sigillo di riempimento modulo orizzontale) macchina è anche conosciuto come a involucro di flusso O confezionatrice a flusso orizzontale. È la macchina confezionatrice più comune nel settore e può essere utilizzata in innumerevoli contesti industriali diversi.

Avvolgere frutti grandi e piccoli.

Pescare, gamberetti, carne, pollo, prosciutto, e altro ancora.

Tutti i tipi di verdure.

Patatine fritte, patatine e altri snack croccanti.

Biscotti, biscotti, e caramelle.

Panetteria compreso il pane, muffin, torte, e altro ancora.

Tagliatelle, ramen, pasta, e tagliatelle istantanee.

Caramelle gommose.

Unghia, bulloni, tubi metallici, e altro ancora.

Siringhe e altri strumenti medici.

Gadget grandi e piccoli.

Forniture alberghiere, saponi, ecc.

Soprattutto per gli imprenditori di e-commerce.

Sigillatura frontale significa che la scanalatura di sigillatura si trova sul lato anteriore dei prodotti finali, il che potrebbe influenzare la dimostrazione del contenuto sulla busta di imballaggio.

Al contrario, sigillatura posteriore significa che la cresta si trova sul lato posteriore del prodotto finale.

Ciò che decide il lato di saldatura è la posizione della pellicola o la direzione delle riprese(dall'alto o dal basso). Possiamo personalizzarlo per te in base alle tue esigenze.

Puoi scegliere una confezionatrice orizzontale in base a queste categorie. Le comuni macchine HFFS differiscono nei seguenti punti 3 modi: dimensione dell'imballaggio, movimenti di taglio, e tipi di flusso.

Per imballare sacchetti di larghezza non superiore a 350 mm.

Per imballare sacchi di larghezza non superiore a 500 mm.

Per imballare sacchi di larghezza non superiore a 680 mm.

Per imballare sacchi di larghezza non superiore a 800 mm.

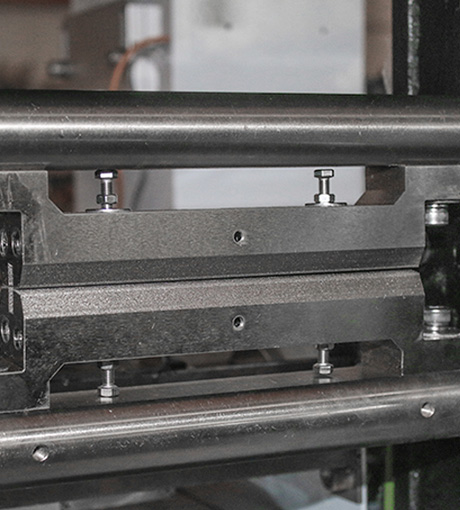

Si muove in un rettangolo(scatola) movimento, e uno dei migliori per produrre sacchetti ben sigillati.

Il metodo di taglio e sigillatura più comune nelle confezionatrici flow pack.

Muoversi direttamente verso l'alto e verso il basso per tagliare e sigillare i sacchetti.

Per oggetti morbidi o più piccoli. Per esempio, prodotti alimentari come torte alla crema e prodotti non alimentari come chiodi e bulloni. Velocità e dimensioni personalizzabili.

Per prodotti più duri, inclusi prodotti alimentari e non alimentari. Velocità e dimensioni del trasportatore a catena personalizzabili.

Clicca per scoprire cosa possiamo fare per te!

Per ricevere la soluzione di pacchetto gratuito ottimale e su misura per le tue esigenze, si prega di compilare e inviare il modulo sottostante.

Approvvigionamento di macchine confezionatrici per sacchetti? Riceverai un preventivo gratuito o maggiori dettagli sulla soluzione dai nostri esperti esperti.