In the bustling world of bread production, efficiency and precision in packaging are paramount. As bakeries and food manufacturers strive to meet the demands of consumers while maintaining product quality, the role of advanced packaging solutions like CHLB PACKING MACHINE becomes increasingly significant. この包括的なガイドでは、, we delve into the realm of bread packaging machines, with a special focus on the innovative capabilities of CHLB PACKING MACHINE, designed to optimize efficiency and elevate performance standards in the industry.

Introduction to Bread Packaging Machines

Bread packaging machines are indispensable tools in modern production facilities, automating the process of packaging loaves, buns, and other baked goods with precision and speed. Among the leading contenders in this arena is CHLB PACKING MACHINE, renowned for its cutting-edge technology and user-friendly design.

Understanding CHLB Bread Packaging Machines

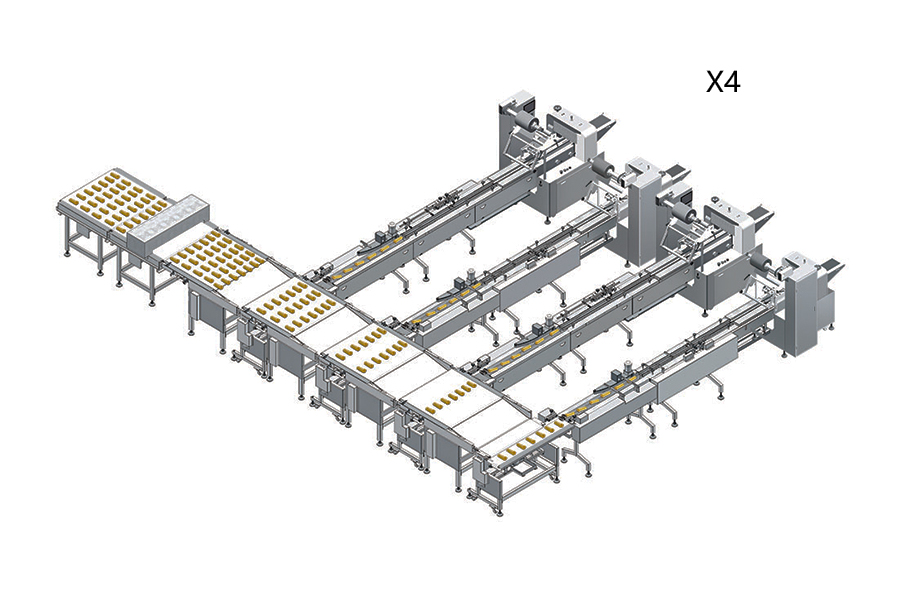

CHLB bread packaging solutions are divided into manual feeding packaging and fully automatic packaging lines. Manual feeding packaging is mainly used by customers with relatively cost-effective labor costs and low output requirements (less than 200 packages per minute).

の fully automatic packaging line is mainly used by customers with high labor costs and high output requirements (over 200 packages per minute).

Benefits of Using Bread Packaging Machines

1. 効率と生産性の向上

- Streamlined Operations: Bread packaging machines automate the packaging process, reducing manual labor and increasing throughput.

- Faster Packaging Speeds: With the ability to package multiple loaves simultaneously, these machines significantly boost production rates.

- Consistent Results: By eliminating human error, bread packaging machines ensure uniform packaging quality with every batch.

2. Improved Hygiene and Food Safety

- Reduced Contamination Risk: Enclosed packaging environments minimize the chances of contamination from external factors.

- Hygienic Sealing: Bread packaging machines utilize sanitary sealing mechanisms to safeguard the freshness and integrity of the product.

- 規制の遵守: Meeting stringent food safety standards, these machines help businesses uphold regulatory compliance and consumer trust.

3. Cost-Effectiveness in Packaging Processes

- Labor Savings: By reducing the need for manual labor, bread packaging machines cut labor costs and allocate resources more efficiently.

- Minimized Waste: Precision packaging minimizes product waste and reduces the likelihood of damaged goods, resulting in cost savings.

- Optimized Material Usage: Bread packaging machines utilize materials efficiently, minimizing excess packaging and reducing overall packaging costs.

4. Customization and Branding Opportunities

- Versatile Packaging Options: Bread packaging machines offer customizable packaging solutions, allowing businesses to cater to diverse consumer preferences.

- Brand Enhancement: With the ability to incorporate branding elements such as logos and product information, these machines enable businesses to strengthen their brand identity.

- Differentiation in the Market: By offering unique packaging designs and features, businesses can differentiate their products and stand out in the competitive marketplace.

5. Extended Shelf Life and Freshness

- Air-Tight Sealing: Bread packaging machines create a hermetic seal that preserves the freshness of the product and extends its shelf life.

- Protection from External Elements: Shielding bread from exposure to air, 水分, and contaminants, these machines maintain product quality over time.

- Enhanced Customer Satisfaction: By delivering fresher, longer-lasting bread to consumers, businesses can enhance customer satisfaction and loyalty.

6. Environmental Sustainability

- Reduced Carbon Footprint: Automated packaging processes consume less energy and produce fewer emissions compared to manual packaging methods.

- Recyclable Materials: Many bread packaging machines support the use of eco-friendly packaging materials, reducing environmental impact.

- Waste Reduction Initiatives: By minimizing product waste and optimizing material usage, bread packaging machines contribute to sustainability efforts and eco-conscious consumer preferences.

7. Scalability and Adaptability

- Scalable Solutions: Bread packaging machines are available in various sizes and configurations, catering to the needs of small bakeries to large-scale production facilities.

- Adaptation to Changing Demands: With adjustable settings and flexible packaging options, these machines can accommodate evolving market trends and consumer demands.

- Investment Protection: As businesses grow, bread packaging machines can be upgraded or expanded to meet increased production requirements, safeguarding the initial investment.

Features and Functionality of CHLB PACKING MACHINE

1. Energy Efficiency

- Sustainable Operation: CHLB PACKING MACHINE incorporates energy-efficient components and technologies to minimize power consumption without compromising performance.

- Cost Savings: By reducing energy usage, businesses can lower their operating costs and achieve long-term savings, making CHLB PACKING MACHINE a financially prudent investment.

2. Air-Tight Packaging

- Hermetic Sealing: With advanced sealing mechanisms, CHLB PACKING MACHINE ensures air-tight packaging, preserving the freshness and quality of the bread while extending its shelf life.

- Protection from Contaminants: The air-tight seal created by CHLB PACKING MACHINE prevents contamination from external elements, maintaining hygienic standards and food safety.

3. Anti-Cutting Material Design

- Enhanced Safety: CHLB PACKING MACHINE is equipped with anti-cutting material features to prevent accidents and injuries during operation, prioritizing worker safety.

- Damage Prevention: By safeguarding against blade-related incidents, this feature minimizes the risk of product and machine damage.

4. Memory Storage Capabilities

- Customizable Settings: CHLB PACKING MACHINE offers memory storage functionality, allowing users to save and recall specific packaging configurations for different bread products.

- Efficient Workflow: By eliminating the need for manual adjustments between production runs, this feature streamlines operations and enhances overall efficiency.

5. Automatic Film Feeding

- Seamless Operation: CHLB PACKING MACHINE features automatic film feeding mechanisms, facilitating continuous packaging without interruptions or delays.

- Reduced Downtime: With automated film feeding, downtime associated with manual film reloading is minimized, maximizing productivity and throughput.

6. Precise Positioning

- Accurate Alignment: CHLB PACKING MACHINE utilizes precision positioning technology to ensure precise alignment of packaging materials, resulting in neat, uniform seals.

- Consistent Packaging Quality: By maintaining precise positioning throughout the packaging process, CHLB PACKING MACHINE delivers consistent and professional-looking results every time.

7. Servo-Driven Performance

- High-Speed Operation: CHLB PACKING MACHINE is powered by servo-driven motors, enabling rapid and precise movements for efficient packaging at optimal speeds.

- Responsive Control: Servo-driven technology provides responsive control over packaging processes, allowing for real-time adjustments to accommodate varying production requirements.

With these advanced features and functionalities, CHLB PACKING MACHINE sets the standard for excellence in bread packaging technology, 比類のない効率を提供します, 安全性, and reliability for businesses in the food industry.

Choosing the Right Bread Packing Machine

Selecting the ideal bread packaging machine can be a daunting task. In this section, we’ll provide valuable insights into the factors to consider when making this crucial decision. さらに, we’ll elucidate why CHLB PACKING MACHINE emerges as the preferred choice for discerning businesses seeking unparalleled performance and reliability.

Setting Up and Operating CHLB PACKING MACHINE

1. On-Site Installation Service

- Convenient Setup: We understand the importance of a hassle-free installation process. That’s why we offer on-site installation services for CHLB PACKING MACHINE, ensuring minimal disruption to your operations.

- Expert Assistance: Our team of trained technicians will visit your facility to install the machine, guiding you through each step of the process to ensure proper setup and functionality.

- Tailored Solutions: We tailor the installation process to your specific needs, taking into account factors such as space constraints and production requirements to optimize the placement and configuration of the machine.

2. Personalized Training Sessions

- Hands-On Learning: In addition to installation, we provide one-on-one training sessions to familiarize your staff with the operation of CHLB PACKING MACHINE.

- Comprehensive Instruction: Our experienced trainers will walk your team through the machine’s features and functionalities, demonstrating proper operation and maintenance procedures.

- Practical Guidance: Through hands-on demonstrations and interactive sessions, we empower your staff to confidently operate CHLB PACKING MACHINE, ensuring smooth and efficient workflow.

- Ongoing Support: Our commitment to your success doesn’t end after installation and training. We’re here to provide continuous support and assistance to address any questions or concerns that may arise during operation.

With our dedicated on-site installation service and personalized training sessions, we strive to make the process of setting up and operating CHLB PACKING MACHINE as seamless and straightforward as possible. Trust us to be your partner in optimizing your bread packaging operations for success.

Maximizing Efficiency with CHLB PACKING MACHINE

Optimizing the performance of CHLB PACKING MACHINE requires a strategic approach. We’ll share expert tips and best practices for maximizing efficiency, along with troubleshooting strategies to address common challenges that may arise.

Maintenance and Care of CHLB PACKING MACHINE

To prolong the lifespan and functionality of CHLB PACKING MACHINE, regular maintenance is essential. We’ll outline the necessary upkeep tasks and cleaning procedures, empowering users to keep their equipment in peak condition.

Frequently Asked Questions (よくある質問)

By the intelligent automatic packing machine, auto weighing, 充填, 封印.

Basically yes, as long as the bakeries are in the suitable range of the machine.

Clean the crumbs after using the machine and wipe it with anti-rust oil regularly depends on the production environment.

はい, the machine is setting a maximum height of product and the Maximum film roll width. As long as the height and the film roll width under the maximum value, the bread packing machine could accomodate different bread sizes. the film roll width is calculate as bread (width + bread height + 10んん)*2.

For the standard bread packing machine, around 1 hour could finish the installation when you received the machine at your factory.

はい, CHLB PACKING MACHINE provides 13 month warranty and life-time technical support.

CHLB PACKING MACHINE is equipped with anti-cutting material features to prevent accidents and injuries during operation, prioritizing worker safety.

はい, basically, the packing machine could also handle packaging for other food products besides bread. But the product have to meet the requirement of the packing machine limiteds.

CHLB packing machine is equipment with the empty bag prevent function to reducing the packaging material waste.

結論

結論は, CHLB PACKING MACHINE represents a paradigm shift in bread packaging technology, empowering businesses to achieve unprecedented levels of efficiency, reliability, and quality. By embracing this innovative solution, bakeries and food manufacturers can stay ahead of the curve, delighting customers and driving success in an increasingly competitive market landscape.