In the fast-paced world of packaging technology, the Horizontal Form Fill Seal (HFFS) machine has emerged as a frontrunner in the realm of efficient and innovative packaging solutions. This comprehensive guide aims to explore the various dimensions of HFFS, unraveling its applications, components, working principles, pros and cons, as well as crucial considerations when choosing the right machine for your specific needs. 게다가, we will delve into maintenance and cleaning procedures to ensure the longevity and optimal performance of your HFFS machine.

What is a Horizontal Form Fill Seal Machine?

에이 수평형 충전 밀봉 (HFFS) 기계 is a state-of-the-art packaging equipment that automates the process of bag making, filling products into the bags, and sealing them horizontally. This ingenious machinery eliminates the need for manual labor, streamlining the production process and significantly improving efficiency.

Applications of Horizontal Form Fill Seal

The applications of HFFS machines are diverse and encompass various industries, including food and beverages, 의약품, 화장품, and household products.

식품산업

source: pinterest

그만큼 food industry benefits immensely from the efficiency and precision provided by horizontal packaging machines. From packaging snacks like potato chips, pretzels, and popcorn to sealing coffee beans, 찻잎, and powdered drink mixes, the HFFS machine ensures that freshness and flavor are retained. This technology also caters to the packaging of sauces, 향료, and condiments, guaranteeing leak-proof and tamper-resistant packaging.

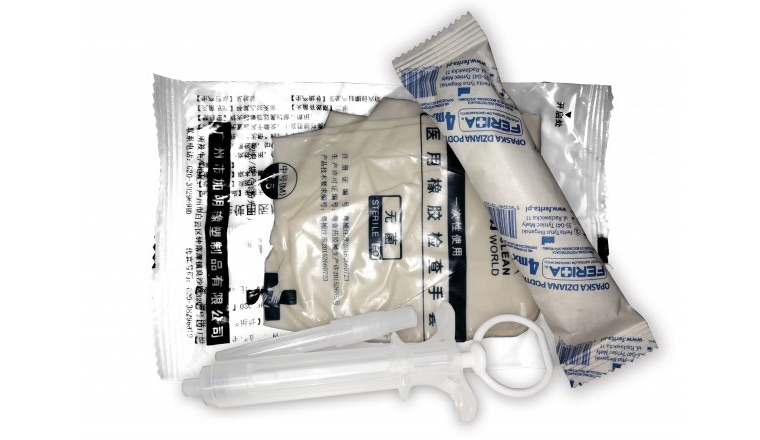

Pharmaceuticals

With the critical requirement for secure and hygienic packaging in the pharmaceutical industry, horizontal packing machine are an invaluable asset. These machines enable the precise measurement and filling of medications, ensuring accurate dosage levels. The airtight seals provided by HFFS machines safeguard the integrity and potency of pharmaceutical products, crucial for patient safety.

Household Item

source: pinterest

In daily life, many items require sophisticated packaging. HFFS machines are used to package diverse items including wet wipes, adhesive tapes, soap, and disposable toothbrush. They provide a secure seal, ensuring the longevity and quality of these products.

애완 동물 사료

그만큼 pet food industry greatly benefits from the capabilities of HFFS machines. These machines efficiently package dry pet food, treats, and snacks, ensuring product freshness and extending shelf life. The reliable seals provided by HFFS machines prevent contamination and preserve the nutritional value of pet food, promoting the health and well-being of animals.

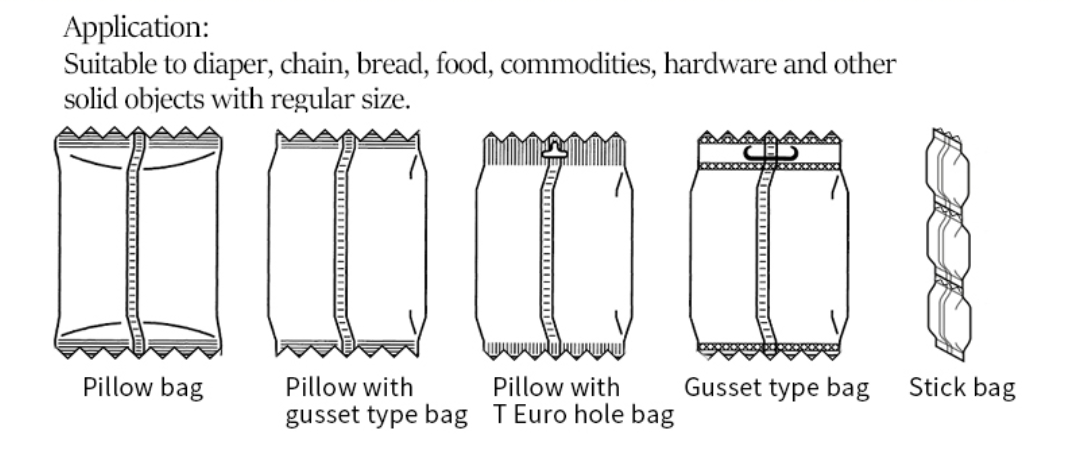

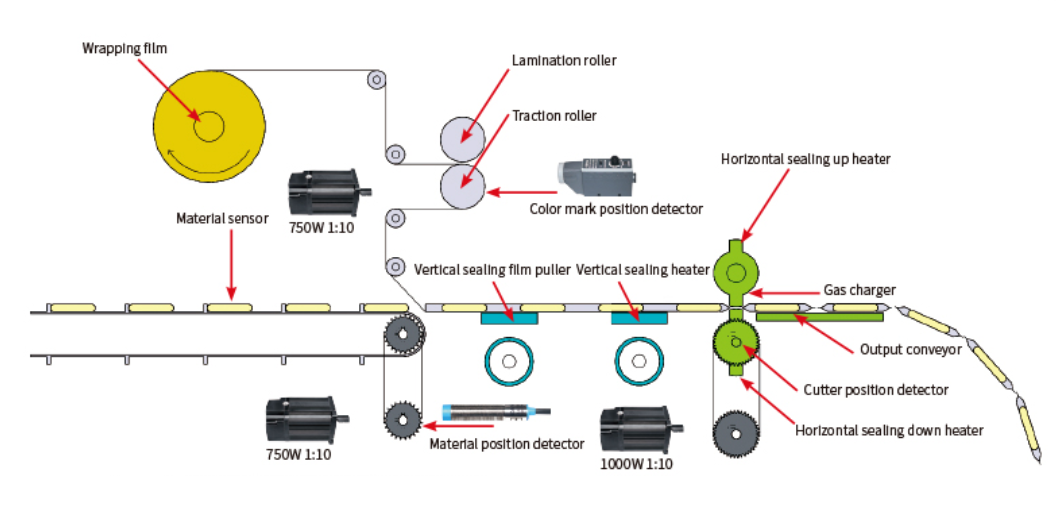

Components of a Horizontal Form Fill Seal Machine

To comprehend the inner workings of an HFFS machine, it is crucial to understand its key components. These include the film unwind, forming plow, filling system, sealing system, cutting system, and discharge conveyor. Each component plays a vital role in the seamless operation of the HFFS machine and contributes to the overall packaging process.

How does Horizontal Form Fill Seal Machine Work?

The HFFS machine operates through a step-by-step breakdown of the filling and sealing process, ensuring the utmost precision and efficiency.

단계 1: Film Unwind

The first step in the HFFS process involves the unwinding of the packaging film roll. This roll of film serves as the essential packaging material that will form the bags. The film unwinding component carefully dispenses the film, ensuring it is fed smoothly and without any obstructions.

단계 2: Forming Plow

Once the film has been unwound, it moves forward to the forming plow. This component is responsible for creating the structure of the bag. The forming plow shapes the film into a tube by sealing the bottom and sides of the bag. The size and shape of the bag can be adjusted based on specific product requirements.

단계 3: 충전 시스템

With the bag structure in place, the filling system takes center stage. This system accurately measures the desired quantity of the product to be packaged and fills it into the bag. The filling system can accommodate a wide range of product types, including liquids, 분말, 과립, and solid items. Precise measurement and consistent filling ensure that each bag contains the correct amount of product.

단계 4: Sealing System

After the bag is filled, the sealing system comes into action. This system employs heat and pressure to seal the top of the bag, ensuring a secure and airtight closure. The sealing system plays a vital role in preserving product freshness, preventing spoilage, and protecting against external contaminants.

단계 5: Cutting System

Once the bag is sealed, the cutting system separates it from the continuous film. This can be done through various methods, such as a rotary cutting blade or a reciprocating knife. The cutting system ensures a clean-cut, detaching the filled bag without compromising its integrity. This step facilitates easy handling, 저장, and transportation of the packaged products.

단계 6: Discharge Conveyor

마지막으로, the filled and sealed bags are transported away from the HFFS machine via the discharge conveyor. This conveyor ensures a smooth transition of the packaged products, guiding them towards the next stage of the production line. The discharge conveyor maintains the order and integrity of the bags, preventing any mishaps or spills.

Pros and Cons of Horizontal Form Fill Seal Machine

Pros

1. Efficiency: HFFS machines streamline packaging processes, increasing productivity and reducing manual labor.

2. Cost-effectiveness: Long-term cost savings can be achieved through optimized production and minimized operational expenses.

3. Product Protection: Airtight seals preserve freshness and quality, extending shelf life and enhancing customer satisfaction.

4. Versatility: HFFS machines can package a wide range of products in various forms, 모양, and sizes.

Cons

1. Initial Investment: HFFS machines require a significant upfront cost.

2. Limited Flexibility: Packaging irregular or oversized items may pose challenges.

3. Maintenance and Training: Regular maintenance and operator training are necessary to ensure optimal performance.

4. Limited Changeover Time: Switching between packaging formats or materials can be time-consuming.

Choosing the Right Machine for Your Needs

Selecting the appropriate HFFS machine requires careful consideration of several factors. These encompass the specific packaging requirements, production capacity, available space, and desired level of automation. 추가적으로, understanding different packaging materials and their compatibility is crucial to ensure optimal performance and product protection. Evaluating speed, efficiency, and customization options will help tailor the machine to your unique needs. 게다가, it is important to choose a reliable packing machine manufacturer.

Maintenance and Cleaning

Proper maintenance and cleaning are vital for the optimal performance and longevity of your Form Fill Seal (FFS) 기계. Follow these key practices:

1. Perform routine maintenance tasks like lubrication, inspection, and calibration to prevent wear and tear.

2. Implement proper cleaning procedures, including removing product residue and sanitizing as needed.

3. Extend the machine’s lifespan by providing operator training, following a preventive maintenance schedule, and referencing OEM recommendations.

4. By prioritizing maintenance and cleaning, you can ensure your FFS machine runs smoothly and efficiently for an extended period.

결론

결론적으로, mastering the art of Horizontal Form Fill Seal requires a comprehensive understanding of its components, working principles, and applications. The ability to select the right machine that aligns with your specific needs, coupled with proper maintenance and cleaning, will ensure efficient, customized, and reliable packaging solutions. Embracing this transformative technology opens doors to increased productivity, improved product safety, and enhanced customer satisfaction in today’s competitive market landscape.