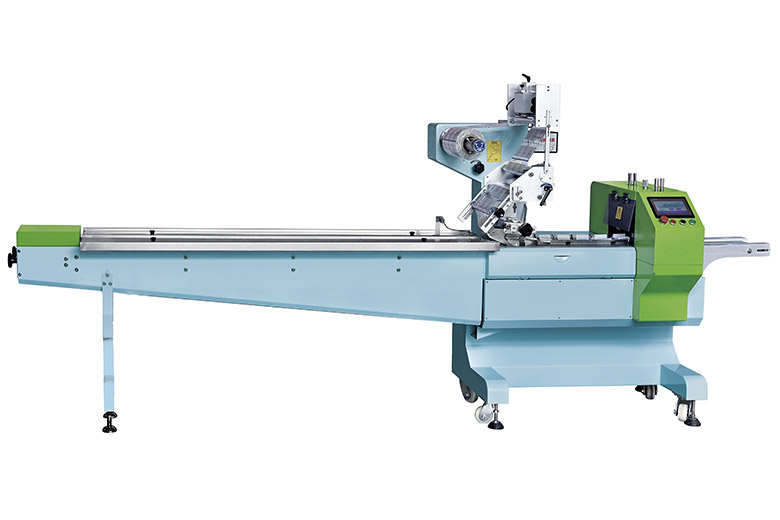

최대 필름 폭 350mm(13.78”), 제품 높이 55mm 이하에 적합(2.17”), 필름 재료 지원 라미레이트 필름. 벨트 컨베이어와 체인 컨베이어 모두.

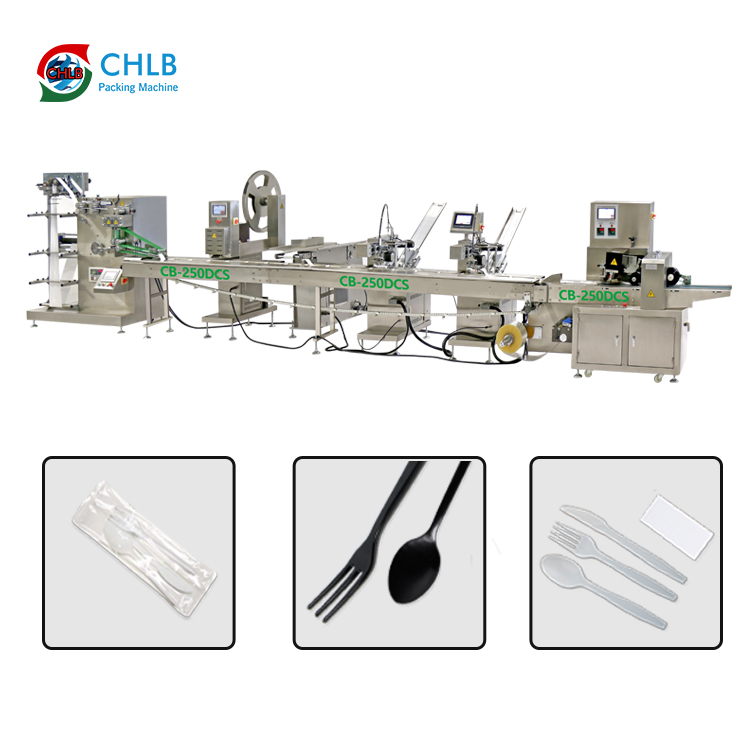

CHLB는 전 세계 산업에 전문 포장 기계를 공급합니다., 그리고 수평 흐름 포장 기계(흐름 래퍼) 우리 목록에서 가장 인기있는 것 중 하나입니다. 포장해야 하는 제품을 기준으로, 기계 조건, 그리고 당신이 사용하는 포장 필름, 우리는 완벽한 솔루션을 맞춤화할 수 있습니다.

최대 필름 폭 350mm(13.78”), 제품 높이 55mm 이하에 적합(2.17”), 필름 재료 지원 라미레이트 필름. 벨트 컨베이어와 체인 컨베이어 모두.

300SZ is a flow packing machine specially design for syringe packaging, with a automatic feeding system to archive a max package speed of 200PPM.

편리한 조작을 위한 캔틸레버식 터치스크린 설계, 박스 모션 커터를 활용하여 효과적인 패키지 밀봉 보장, 순수 PE 필름을 사용하여 포장재 비용 절감. 이 기계는 최대 필름 폭 680mm를 지원합니다.(26.77”) 최대 제품 높이는 110mm입니다.(4.33”).

박스 모션 조로 유지 관리가 간단하고 밀폐된 폐쇄가 보장됩니다.. 포장 비용을 절약하기 위해 순수 PE 필름을 지원하십시오., 최대 필름 폭 450mm 수용(17.72”), 최대 제품 높이 90mm 가능(3.54”).

튜브 포장 기계는 최대 길이가 다음과 같은 강철 튜브 및 파이프용으로 특별히 설계되었습니다. 6 meters (236 inches). It features an automatic air cylinder-based feeding system and a collection bracket for finished products.

The horizontal flow pack machine features a compact design, accommodating a maximum film width of 350mm. It is suitable for products with a height of max 60mm and can achieve a maximum packaging speed of 200PPM.

프리미엄 소재 활용 및 유능한 엔지니어 채용으로, 우리는 기존 포장 효율성을 향상시키기 위해 광범위한 고성능 흐름 포장 기계를 제공하는 데 능숙합니다., 투자비용을 빠르게 회수할 수 있습니다.. 당사 Flow Wrap Machine의 특징은 다음과 같습니다.:

브랜드 서보 모터는 속도와 동작 명령을 정밀하게 제어합니다..

정밀한 인덕터, 자체 조절 제어 시스템과 지능형 사용자 제어 패널은 높은 정확성과 쉬운 작동을 보장합니다..

인건비 절감 및 효율성 향상을 위한 자동화 포장 솔루션.

인건비 절감 및 효율성 향상을 위한 자동화 포장 솔루션.

우리는 SUS를 사용합니다 304 식품 생산 요구 사항을 충족하는 스테인레스 스틸, 우리는 귀하의 운영 직원을 보호하기 위해 사용자 친화적인 디자인을 제공합니다..

Food grade stainless steel to ensure hygiene & safety. 기계 부품은 SS304 및 SS316을 선택할 수 있습니다..

빠른, 정확한, & customizable according to your needs. 장착된 패널에서 언제든지 세부 사항을 조정할 수 있습니다..

HFFS(수평형 충전 밀봉) 기계 로도 알려져 있습니다. 흐름 래퍼 또는 수평 흐름 포장 기계. 업계에서 가장 일반적인 포장 기계이며 수많은 다양한 산업 환경에서 사용할 수 있습니다..

크고 작은 과일을 포장.

물고기, 새우, 고기, 닭, 햄, 그리고 더.

모든 종류의 야채.

작은 조각, 칩 및 기타 바삭바삭한 스낵.

쿠키, 비스킷, 그리고 사탕.

빵을 포함한 베이커리, 머핀, 파이, 그리고 더.

국수, 라면, 파스타, 그리고 인스턴트 라면.

구미사탕.

손톱, 볼트, 금속 튜브, 그리고 더.

주사기 및 기타 의료 도구.

크고 작은 가제트.

호텔 용품, 비누, 등.

특히 전자상거래 사업주에게.

전면 씰링 밀봉 능선이 최종 제품의 전면에 있어 포장 백의 내용물 표시에 영향을 미칠 수 있음을 의미합니다..

반대로, 뒷면 밀봉 능선이 최종 제품의 뒷면에 있음을 의미합니다..

밀봉면을 결정하는 것은 필름 위치나 촬영 방향입니다.(위에서 또는 아래에서). 우리는 귀하의 필요에 따라 귀하를 위해 맞춤화할 수 있습니다.

이러한 카테고리를 기반으로 수평 흐름 래퍼를 선택할 수 있습니다.. 일반적인 HFFS 기계는 다음과 같은 차이점이 있습니다. 3 방법: 포장 크기, 절단 동작, 및 흐름 유형.

폭이 350mm 이하인 포장 백의 경우.

폭이 500mm 이하인 포장백의 경우.

폭이 680mm 이하인 포장 백의 경우.

폭이 800mm 이하인 포장백의 경우.

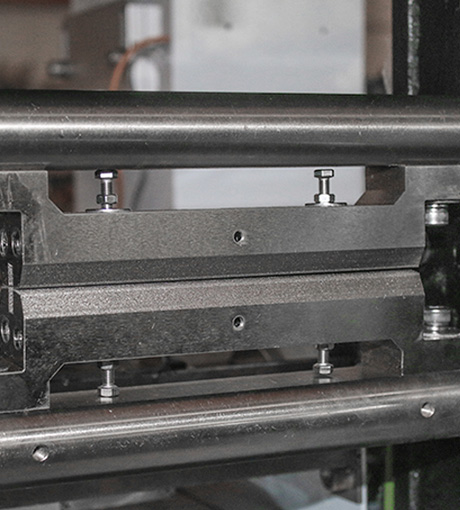

직사각형으로 움직인다(상자) 운동, 단단히 밀봉된 가방을 생산하는 최고의 제품 중 하나입니다..

플로우 래퍼 기계에서 가장 일반적인 절단 및 밀봉 방법.

가방을 자르고 밀봉하기 위해 똑바로 위쪽 및 아래쪽으로 이동.

부드럽거나 작은 품목의 경우. 예를 들어, 크림 케이크와 같은 식품과 못, 볼트와 같은 비식품. 속도 및 크기 맞춤 설정 가능.

식품 및 비식품을 포함한 더 단단한 제품의 경우. 체인 컨베이어 속도 및 크기 맞춤 설정 가능.

우리가 당신을 위해 무엇을 할 수 있는지 알아보려면 클릭하세요!

귀하의 요구에 맞는 최적의 무료 패키지 솔루션을 받으려면, 아래 양식을 작성하여 제출해주세요..

소싱 백 포장 기계? 경험이 풍부한 전문가로부터 무료 견적을 받거나 솔루션에 대한 자세한 내용을 얻을 수 있습니다..