This biscuit sandwiching machine can cream up to 600 creamed biscuits per minute. You can settle easily the package quantities and biscuits layout to 1×1, 1×2, 1×3, , 2×1, 2×2, 2×3 in system.

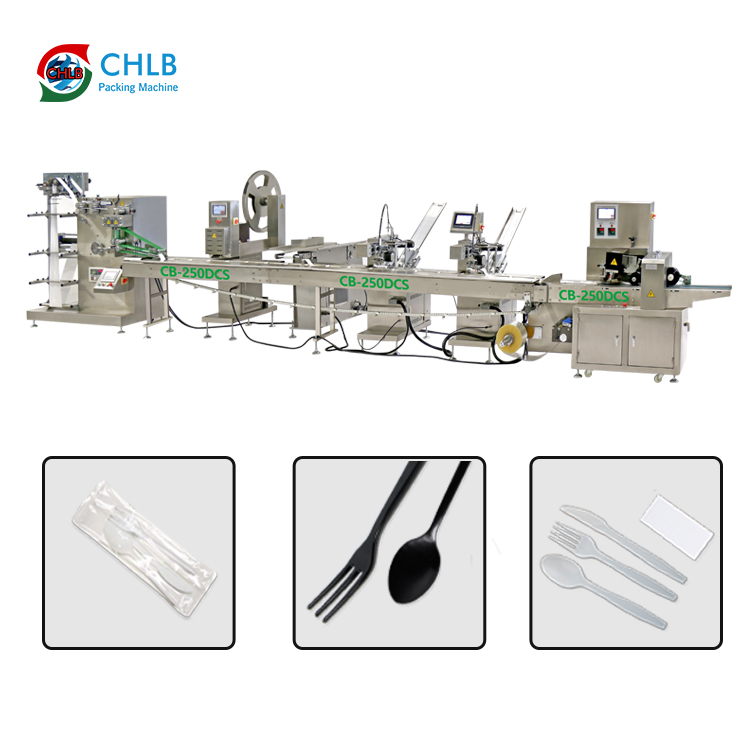

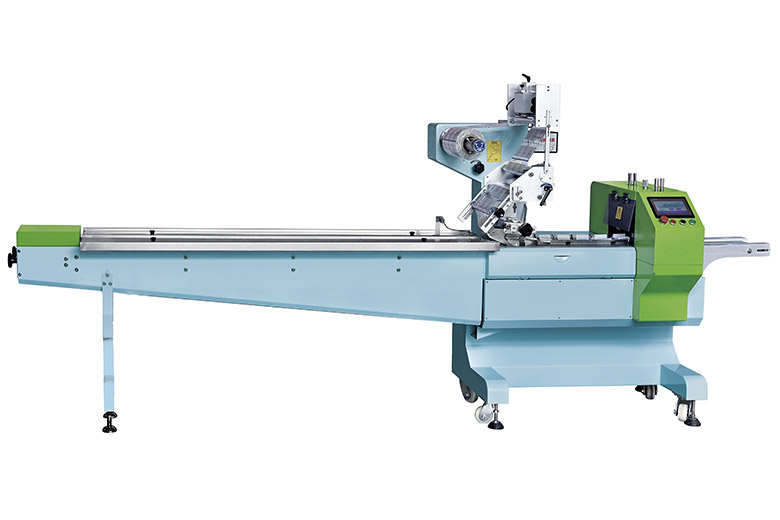

CHLB supplies professional packaging machines for industries around the globe, and the horizontal flow packaging machine(flow wrapper) is one of the most popular on our list. Based on the products you have to package, the machine conditions, and the packaging film you are using, we can tailor a perfect solution.

This biscuit sandwiching machine can cream up to 600 creamed biscuits per minute. You can settle easily the package quantities and biscuits layout to 1×1, 1×2, 1×3, , 2×1, 2×2, 2×3 in system.

Fully automatic cream sandwich and packaging line, free your hand,up to 1200 biscuits/minute. Easily setting the counting number 4 to 20 pcs of creamed biscuits per bags.

The sandwich biscuit packing line is capable of producing up to 1200 sandwich biscuits per minute. Suitable for biscuits size from 35 to 65mm. The biscuits can have a thickness of 4 to 8mm.

300SK is a kind of premade bag packing machine, but especially design for socks packaging, and it’s a new type of fully automatic socks packing machine.

A common application of the E-commerce package involves incorporating air bubble wrap roll material to bolster product protection. Max film width is 450mm(17.72”), suitable for product height under 90mm(3.54”)

Applicable for large products, allow to pack the product maximum height is 200mm(7.87”), and the maximum film width is 800mm(31.5”). PE film supported.

By utilizing premium materials and employing capable engineers, we are competent in providing an extensive range of high-performance flow wrap machines to improve your existing packing efficiency, and you can recover the cost of investment quickly. Features of our Flow Wrap Machine are as follows:

Branded servo motors precisely control the speed and action command.

Precise inductors, self-regulating control systems and intelligent user control panels ensure the high accuracy and easy operation.

Automated packing solutions to save labor cost and improve efficiency.

Automated packing solutions to save labor cost and improve efficiency.

We use SUS 304 stainless steel to meet the requirements of food production, and we provide the user-friendly design to protect your operating staff.

Food grade stainless steel to ensure hygiene & safety. You can choose SS304 and SS316 for machine parts.

Fast, accurate, & customizable according to your needs. You can always adjust details on the equipped panel.

HFFS(Horizontal Form Fill Seal) machine is also known as a flow wrapper or horizontal flow packaging machine. It’s the most common packaging machine in the industry and can be used in countless different industrial settings.

Wrapping fruits big and small.

Fish, shrimps, meat, chicken, ham, and more.

All kinds of vegetables.

Chips, crisps and other crunchy snacks.

Cookies, biscuits, and candies.

Bakery including bread, muffins, pies, and more.

Noodles, ramen, pasta, and instant noodles.

Gummy candies.

Nails, bolts, metal tubes, and more.

Syringes and other medical tools.

Gadgets big and small.

Hotel supplies, soaps, etc.

Especially for e-commerce business owners.

Front sealing means that the sealing ridge is on the front side of the final products which might affect the demonstration of the contents on the packaging bag.

On the contrary, back sealing means the ridge is on the back side of the final product.

What decides the sealing side is the film position or the filming direction(from the top or from below). We can customize it for you according to your needs.

You can choose a horizontal flow wrapper based on these categories. Common HFFS machines differ in the following 3 ways: packaging size, cutting motions, and flow types.

For packaging bags that are no more than 350mms wide.

For packaging bags that are no more than 500mms wide.

For packaging bags that are no more than 680mms wide.

For packaging bags that are no more than 800mms wide.

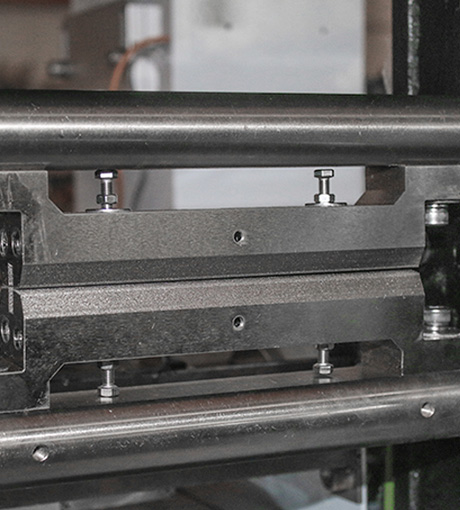

Moves in a rectangular(box) motion, and one of the best to product tightly sealed bags.

Most common cutting and sealing method in flow wrapper machines.

Moving straight upward and downward to cut and seal the bags.

For soft or smaller items. For example, food product like cream cake and non-food product like nails and bolts. Speed and size customizable.

For harder products including food and non-food items. Chain conveyer speed and size customizable.

Click to find out what we can do for you!

To receive the optimal free package solution tailored to your needs, kindly complete and submit the form below.

Sourcing bag packaging machines? You will get a free quote or get more details about the solution from our experienced experts.