CHLB provides professional and efficient thermoforming machines for food packaging industry, including meat, seafood, fruits, and vegetables.

Besides, thermoforming packing machines are widely used for pharmaceutical products, hardware components, medical equipment, etc.

It seems we can't find what you're looking for.

The native frame is constructed with a 30mm thick high-strength alloy aluminum structure, which undergoes precision machining through high-precision gantry planning and gantry milling. In comparison to steel structures and regular aluminum sheet structures, it exhibits significant features such as high mechanical strength, structural stability, resistance to deformation, and excellent precision.

High pumping efficiency, high vacuum degree, low noise, stable and reliable quality, long service life and other remarkable features, fast pumping speed

The vacuum and forming air system of this machine is advanced, ingenious and unique in design, which improves the working efficiency of the whole machine by more than 10%, which is at the international advanced level.

The control system of this machine adopts the world-renowned Japanese Mitsubishi 10-inch color large-screen touch screen, programmable logic controller (PLC) to control the stepping system, servo motor, high operating precision, and automatic and stable coordination of various actions to ensure reliable operation of the machine and simple and convenient use. . The button switch adopts the product of the French "Schneider" electric company, with beautiful appearance and safe and reliable operation.

This machine can design molds according to your requirements. The mold replacement is simple and fast, and it is very convenient for the packaging of multi-variety and multi-standard commodities. It truly realizes the multi-purpose of one machine and greatly improves the scope of use of the machine.

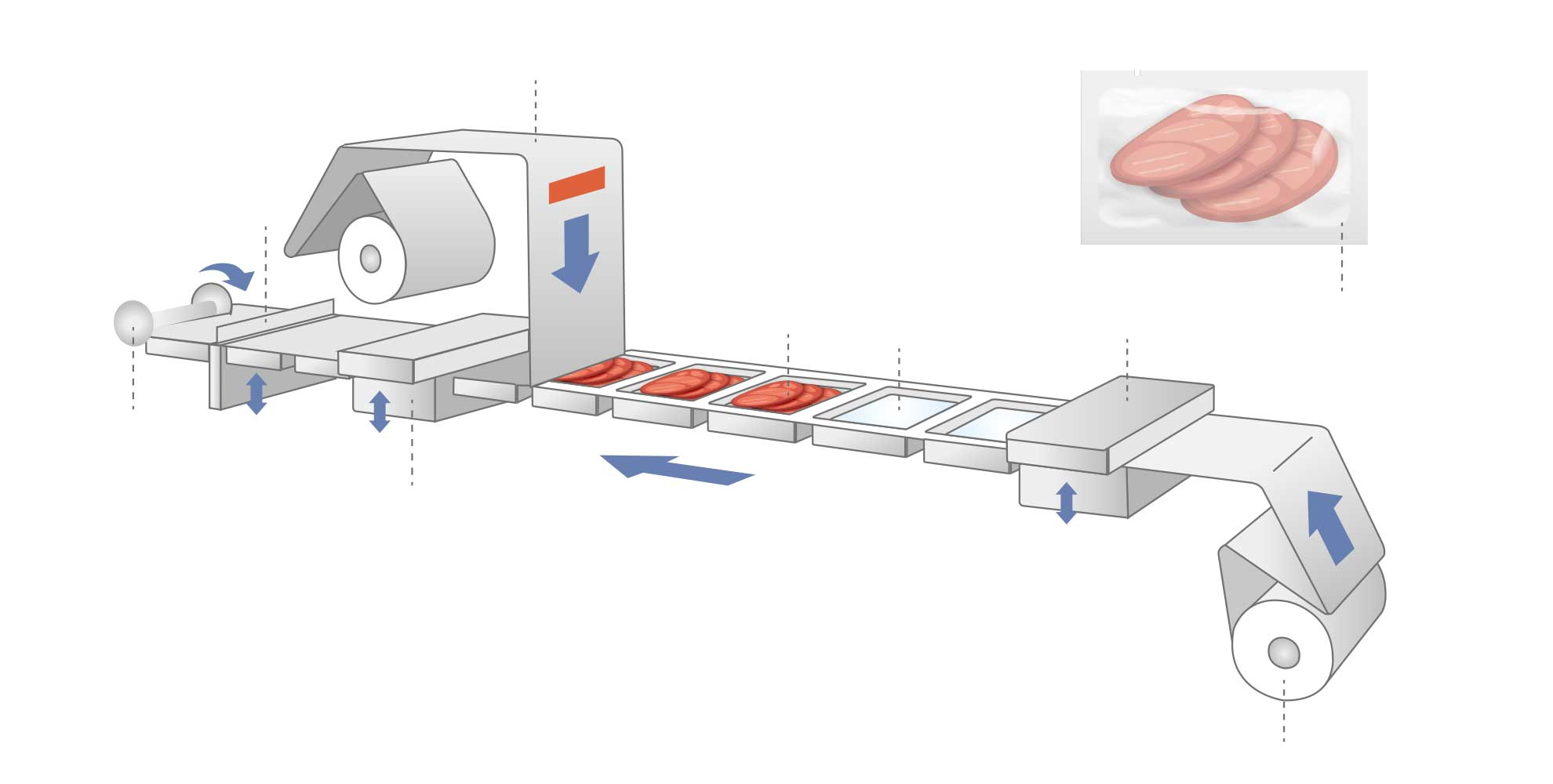

A thermoforming packaging machine, also known as a stretch film packing machine, is used for vacuum packaging or modified atmosphere packaging (MAP). This method is widely used for creating containers, trays, and blister packs, offering a cost-effective solution for high-volume, custom packaging needs.

In the thermoforming process, a plastic sheet is heated until it becomes soft and pliable, then shaped into the desired form using a mold. The machine applies vacuum or pressure to ensure the plastic takes the shape of the mold before cooling and trimming it into the final packaging product.

Thermoforming packaging machines are perfect for vacuum packaging, aeration, skin packaging, and more. They offer versatile solutions for a wide range of products across multiple industries, ensuring superior protection and preservation.

Meat, seafood, ham, sausage, and more.

Ready-to-eat snacks, like fish dried, eggs, etc.

Fruits, jujube fruit, vegetables, or pickles

Granule products like grains, rice, nuts, etc.

Thermoforming packaging machines are ideal for packaging medical supplies and hardware components to enhance protection.

Syringes

Masks

Medical cotton swab

Hardware

Sourcing bag packaging machines? You will get a free quote or get more details about the solution from our experienced experts.

To receive the optimal free package solution tailored to your needs, kindly complete and submit the form below.