Esta sanduicheira de biscoitos pode fazer creme até 600 biscoitos cremosos por minuto. Você pode definir facilmente as quantidades dos pacotes e o layout dos biscoitos para 1×1, 1×2, 1×3, , 2×1, 2×2, 2×3 no sistema.

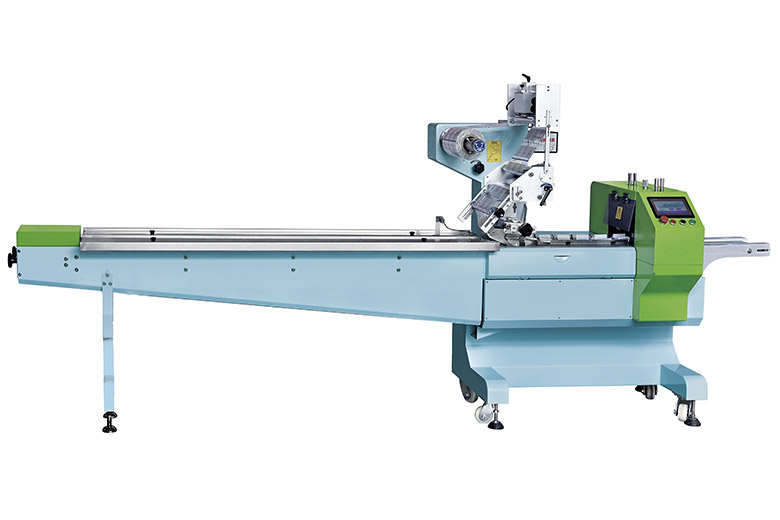

A CHLB fornece máquinas de embalagem profissionais para indústrias em todo o mundo, e o máquina de embalagem de fluxo horizontal(empacotador de fluxo) é um dos mais populares da nossa lista. Com base nos produtos que você precisa embalar, as condições da máquina, e o filme de embalagem que você está usando, podemos personalizar uma solução perfeita.

Esta sanduicheira de biscoitos pode fazer creme até 600 biscoitos cremosos por minuto. Você pode definir facilmente as quantidades dos pacotes e o layout dos biscoitos para 1×1, 1×2, 1×3, , 2×1, 2×2, 2×3 no sistema.

Linha de embalagem e sanduíche de creme totalmente automática, liberte sua mão,até 1200 biscoitos/minuto. Configurando facilmente o número de contagem 4 para 20 unidades de biscoitos cremosos por saco.

A linha de embalagem para biscoitos recheados é capaz de produzir até 1200 biscoitos sanduíche por minuto. Adequado para biscoitos de tamanho desde 35 para 65 mm. Os biscoitos podem ter uma espessura de 4 a 8mm.

300SK é um tipo de máquina de embalagem de sacos pré-fabricados, mas especialmente design para embalagens de meias, e é um novo tipo de máquina embaladora de meias totalmente automática.

Uma aplicação comum do pacote de comércio eletrônico envolve a incorporação de material de rolo de plástico bolha de ar para reforçar a proteção do produto. A largura máxima do filme é de 450 mm(17.72”), adequado para altura do produto inferior a 90 mm(3.54”)

Aplicável para produtos grandes, permitir embalar o produto com altura máxima de 200mm(7.87”), e a largura máxima do filme é 800 mm(31.5”). Filme PE suportado.

Utilizando materiais premium e empregando engenheiros competentes, somos competentes em fornecer uma ampla gama de máquinas de embalagem flow pack de alto desempenho para melhorar a eficiência de sua embalagem existente, e você pode recuperar o custo do investimento rapidamente. As características da nossa máquina Flow Wrap são as seguintes:

Servomotores de marca controlam com precisão a velocidade e o comando de ação.

Indutores precisos, sistemas de controle autorreguláveis e painéis de controle de usuário inteligentes garantem alta precisão e fácil operação.

Soluções de embalagem automatizadas para economizar custos de mão de obra e melhorar a eficiência.

Soluções de embalagem automatizadas para economizar custos de mão de obra e melhorar a eficiência.

Usamos o SUS 304 aço inoxidável para atender aos requisitos da produção de alimentos, e fornecemos um design fácil de usar para proteger sua equipe operacional.

Food grade stainless steel to ensure hygiene & safety. Você pode escolher SS304 e SS316 para peças de máquinas.

Rápido, preciso, & customizable according to your needs. Você sempre pode ajustar os detalhes no painel equipado.

HFFS(Selo de preenchimento de formulário horizontal) máquina também é conhecido como empacotador de fluxo ou máquina de embalagem de fluxo horizontal. É a máquina de embalagem mais comum na indústria e pode ser usada em inúmeros ambientes industriais diferentes.

Embrulhando frutas grandes e pequenas.

Peixe, camarões, carne, frango, presunto, e mais.

Todos os tipos de vegetais.

Batatas fritas, batatas fritas e outros salgadinhos crocantes.

Biscoitos, biscoitos, e doces.

Padaria incluindo pão, muffins, tortas, e mais.

Macarrão, ramen, massa, e macarrão instantâneo.

Doces de goma.

Unhas, parafusos, tubos metálicos, e mais.

Seringas e outras ferramentas médicas.

Gadgets grandes e pequenos.

Suprimentos para hotéis, sabonetes, etc..

Especialmente para proprietários de empresas de comércio eletrônico.

Vedação frontal significa que a crista de vedação está na parte frontal dos produtos finais, o que pode afetar a demonstração do conteúdo na embalagem.

Pelo contrário, vedação traseira significa que a crista está na parte de trás do produto final.

O que decide o lado da vedação é a posição do filme ou a direção da filmagem(de cima ou de baixo). Podemos personalizá-lo para você de acordo com suas necessidades.

Você pode escolher um flow wrapper horizontal com base nessas categorias. Máquinas HFFS comuns diferem no seguinte 3 caminhos: tamanho da embalagem, movimentos de corte, e tipos de fluxo.

Para sacos de embalagem com largura não superior a 350 mm.

Para sacos de embalagem com largura não superior a 500 mm.

Para sacos de embalagem com largura não superior a 680 mm.

Para sacos de embalagem com largura não superior a 800 mm.

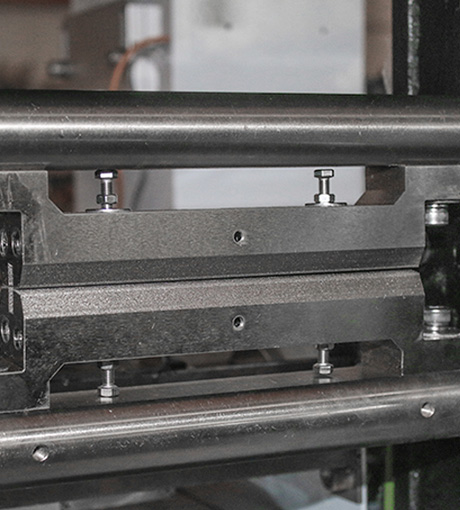

Move-se em um retângulo(caixa) movimento, e um dos melhores para produzir sacos hermeticamente fechados.

Método de corte e selagem mais comum em máquinas embaladoras flow pack.

Movendo-se para cima e para baixo para cortar e selar os sacos.

Para itens macios ou menores. Por exemplo, produtos alimentícios, como bolo de creme, e produtos não alimentícios, como pregos e parafusos. Velocidade e tamanho personalizáveis.

Para produtos mais duros, incluindo alimentos e não alimentares. Velocidade e tamanho do transportador de corrente personalizáveis.

Clique e descubra o que podemos fazer por você!

Para receber a solução ideal de pacote gratuito adaptada às suas necessidades, por favor preencha e envie o formulário abaixo.

Fornecimento de máquinas de embalagem de sacos? Você receberá um orçamento gratuito ou obterá mais detalhes sobre a solução de nossos especialistas experientes.